Lime slurry is a common decoration material. It is made of lime as the main component and is processed and treated in a series of ways. It has excellent bonding and curing properties and is widely used in construction, decoration, repair and other fields.

CRQ calcium hydroxide production line, as a key equipment for producing calcium hydroxide, has a close relationship with limestone slurry. Limestone slurry is not only an important raw material for CRQ production line, but also plays an irreplaceable role in many fields.

Preparation of limestone slurry

The preparation of lime slurry mainly includes the drying of lime, slaking of lime and stirring of lime slurry. First, limestone is dried at high temperature through processes such as crushing and grinding to make its water content reach a certain level. Then, at an appropriate temperature, the dried limestone is reacted with water to produce lime, that is, lime slaking. Finally, the lime is stirred with an appropriate amount of water to form lime slurry.

The key to the preparation of lime slurry is to control the water content and slaking temperature of lime, as well as the time and speed of the stirring process. Only when it is prepared under appropriate conditions can high-quality lime slurry be obtained.

Limestone slurry

Flue gas desulfurization: In industrial fields such as thermal power plants, coal combustion will produce a large amount of flue gas containing sulfur dioxide. Limestone slurry can be used for flue gas desulfurization. The principle is that limestone slurry reacts chemically with sulfur dioxide to produce substances such as calcium sulfite and calcium sulfate, thereby removing sulfur dioxide from flue gas and reducing environmental pollution problems such as acid rain.

Wastewater treatment: It can be used to adjust the pH value of wastewater to make acidic wastewater neutral or nearly neutral, which is convenient for subsequent treatment and discharge. At the same time, it can also react with some heavy metal ions in wastewater to form precipitation, thereby removing heavy metal pollutants in wastewater.

Chemical raw materials: After further processing, limestone slurry can be used as a raw material for the production of chemical products such as calcium carbonate, calcium chloride, and calcium sulfate. For example, light calcium carbonate is an important chemical filler, which is widely used in rubber, plastics, coatings, inks and other industries, and can improve product performance and reduce production costs.

Building materials: In the construction industry, limestone slurry can be used to prepare building gypsum, cement and other materials. Building gypsum has good fire resistance, thermal insulation and decorative properties, and is often used for interior wall decoration; cement is an indispensable cementitious material in modern buildings, used to make concrete, mortar, etc.

Agricultural application: In agriculture, limestone slurry can be used to improve acidic soil. It can neutralize acidic substances in the soil, increase the pH value of the soil, improve the soil structure, and increase the content of nutrients such as calcium and magnesium in the soil, which is beneficial to the growth of crops.

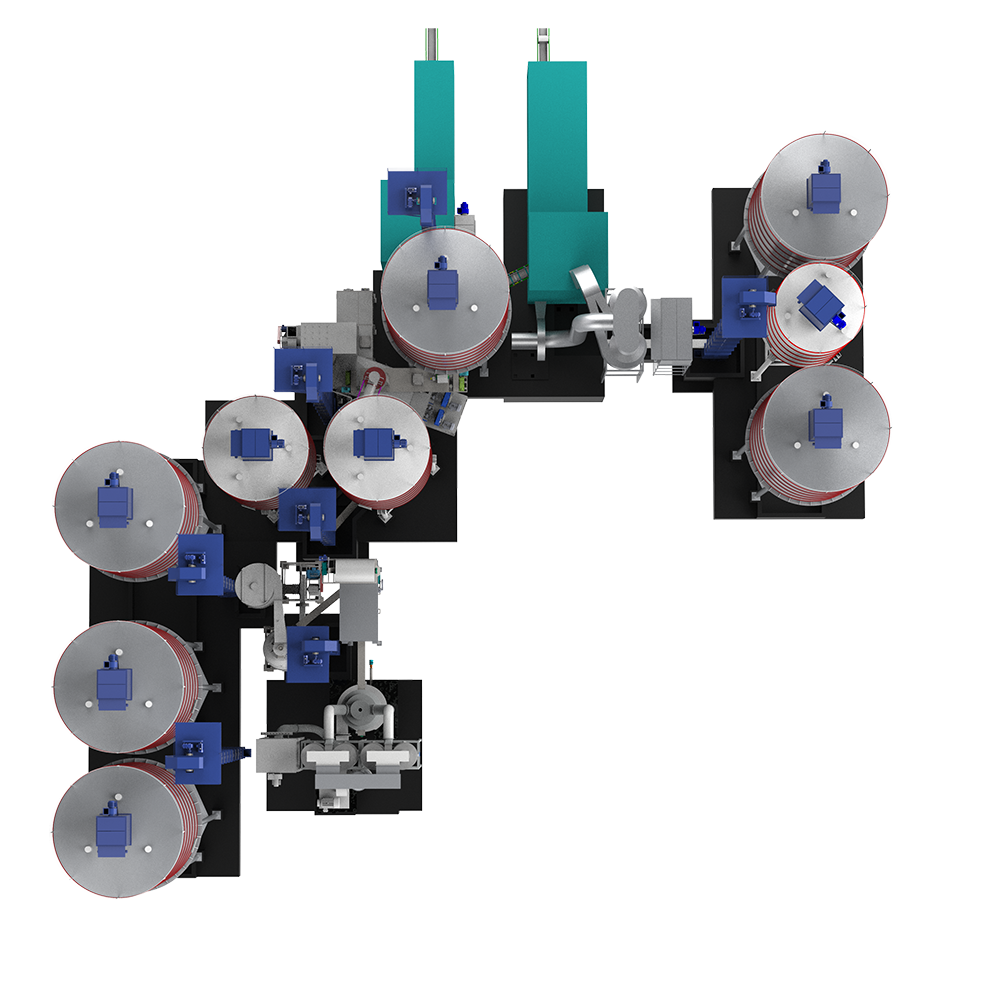

Functional characteristics of CRQ calcium hydroxide production line

The whole production line is mainly composed of CRSH series lime digester (dynamic digestion), delayed digestion bin (static digestion), CRHG series calcium hydroxide special mill, CRXF series calcium hydroxide powder selector through different permutations and combinations. Based on the overall investment of the production line, plant area, total energy consumption, raw material quality, operating cost, powder type application domain and competitive advantage and other factors, the production process and construction scheme design are customized. The technology and process are advanced, and energy saving and environmental protection, intelligent control, product quality improvement, and operating cost reduction are achieved. It is an efficient, green and environmentally friendly calcium hydroxide powder intelligent production line.

Application scenarios of CRQ calcium hydroxide production line

The production capacity of CRQ calcium hydroxide production line is 5~30t/h, which is mainly used in metallurgy, construction, medicine, food, sugar and chemical industry, papermaking, feed additives, fertilizer agriculture, petroleum additives, waste incineration flue gas treatment, sewage treatment, coal-fired power plant desulfurization, bleaching powder manufacturing and other aspects.

Cronus CRQ calcium hydroxide production line - leading technology, excellent quality, high efficiency

With an advanced calcium hydroxide production line, CRONUS is undoubtedly your ideal choice. From the fine processing of raw materials to the automated production process, each link has been carefully designed and optimized to effectively reduce production costs and create higher value for you.

If you have the need to invest in the construction of a calcium hydroxide production line, please feel free to contact us. Our professional team will provide you with detailed project planning, high-quality product services and perfect after-sales support to help you seize the initiative in the field of calcium hydroxide production.