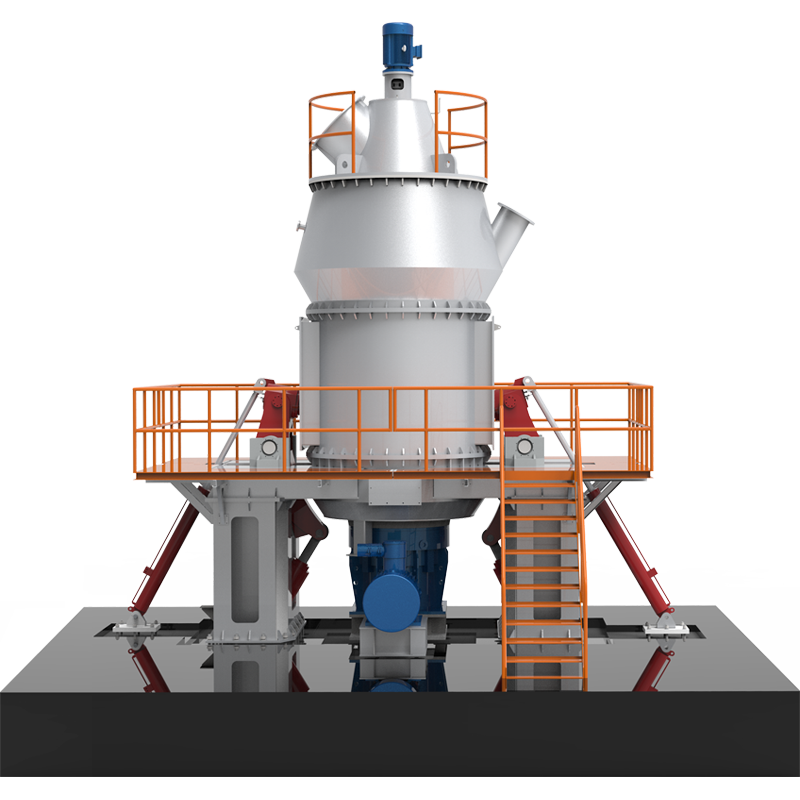

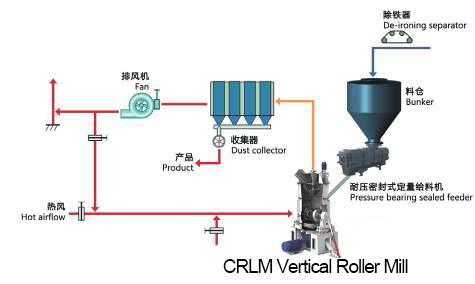

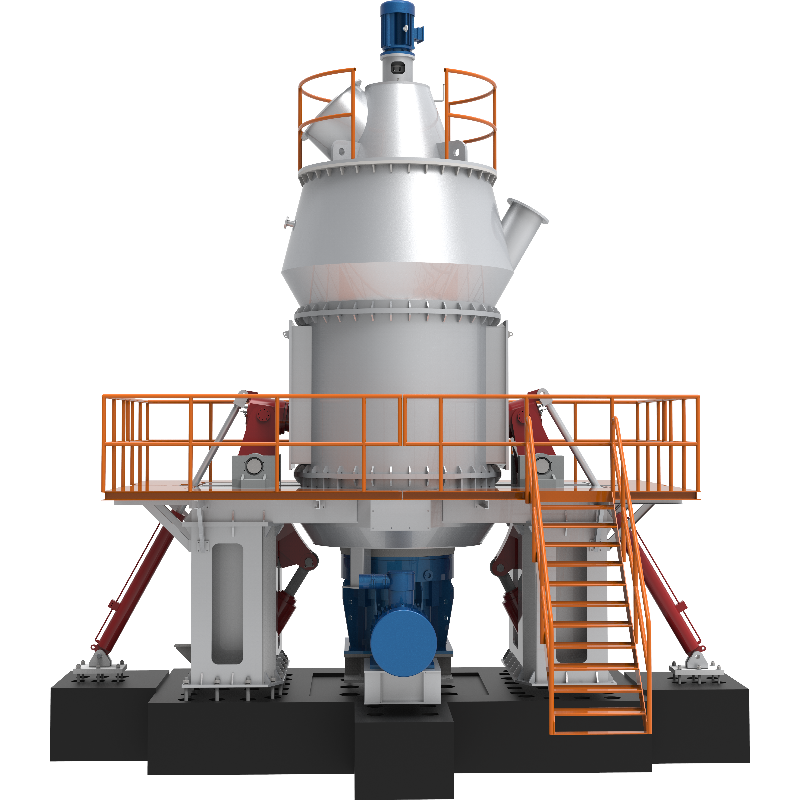

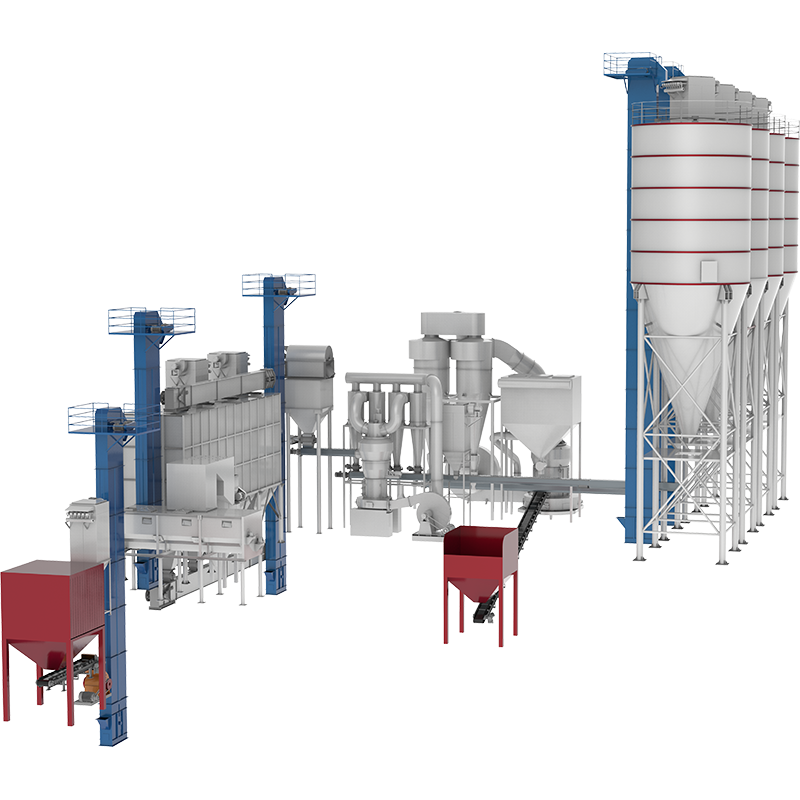

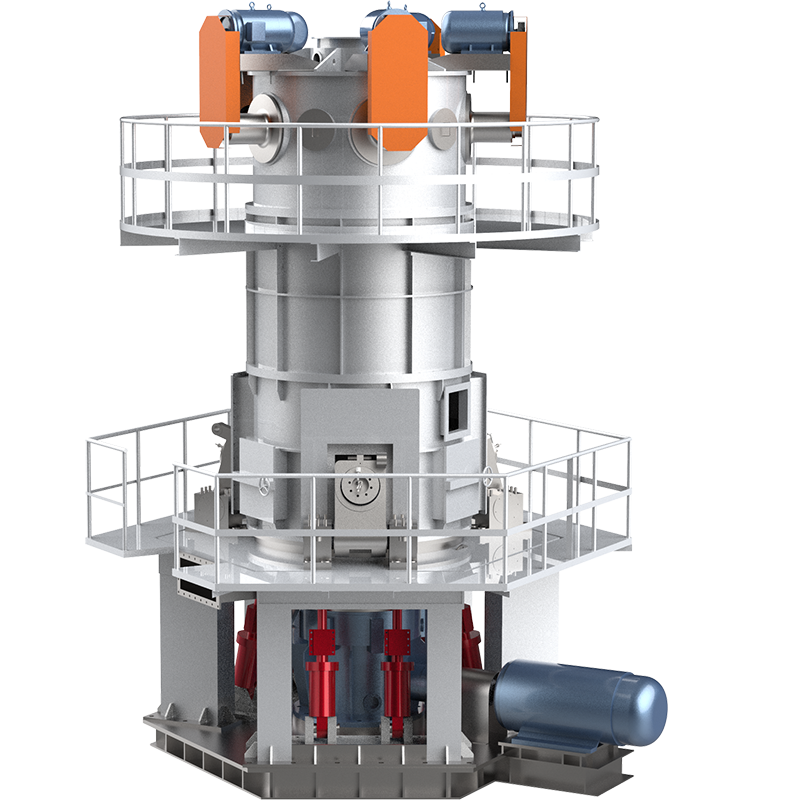

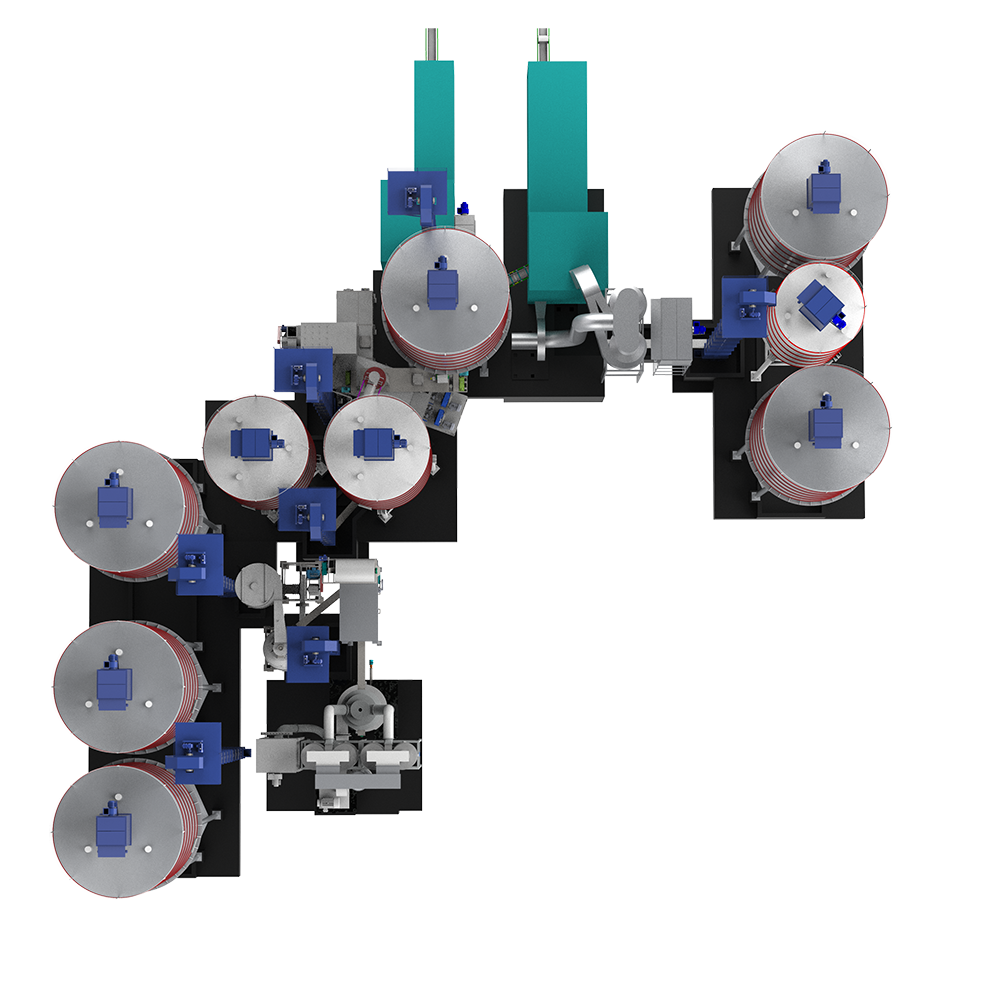

CRLM Vertical Roller Mill for Mineral Processing

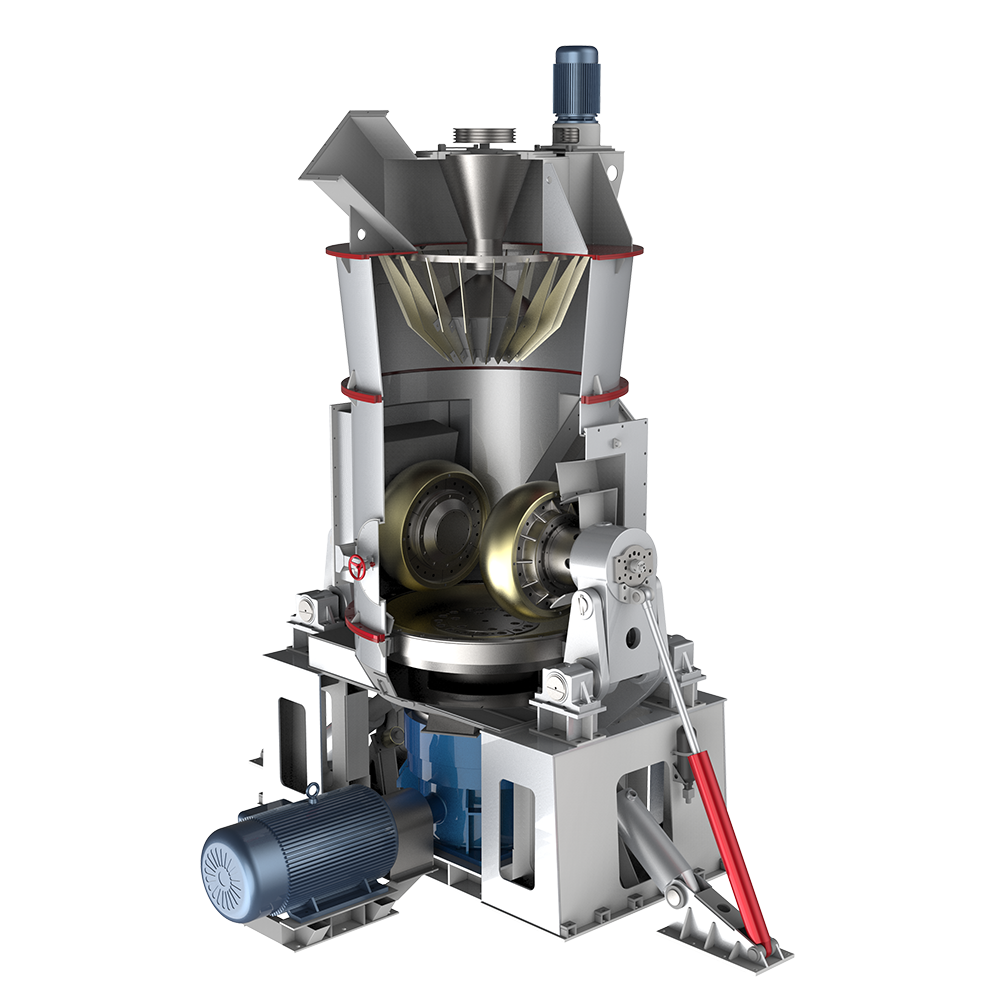

CRLM vertical mill can be widely used in cement, metallurgy chemical industry, non-metallic ore, non-ferrous metals ore powder grinding, and electric power. Based on the absorption of advanced technologies of a famous International Corporation and with more than 50 years of experience in grinding mill production, Guikang has launched the GKLM2800K vertical mill which integrates […]