Applications of Ultrafine Calcium Carbonate Powder

Ultrafine calcium carbonate powder, characterized by its small particle size (typically ranging from nanometers to a few micrometers) and high surface area, is widely used across various industries due to its unique physical and chemical properties. Below are its key applications:

- Plastics Industry

- Acts as a filler to enhance mechanical properties (e.g., stiffness, impact resistance) and reduce production costs.

- Improves surface finish, dimensional stability, and thermal resistance in plastic products.

- Rubber Industry

- Reinforces rubber products, improving tensile strength, abrasion resistance, and elasticity.

- Reduces material costs while maintaining performance in tires, seals, and belts.

- Coatings and Paints

- Serves as an extender pigment to improve opacity, dispersion, and weather resistance.

- Enhances viscosity control, gloss, and durability in water-based and solvent-based coatings.

- Paper Manufacturing

- Used as a coating pigment to improve paper brightness, smoothness, and printability.

- Reduces reliance on wood pulp, lowering production costs and environmental impact.

- Pharmaceuticals and Nutraceuticals

- Employed as a calcium supplement in tablets and dietary products due to its high bioavailability.

- Acts as an excipient to control drug release rates in formulations.

- Food Additives

- Approved as a food-grade additive (E170) for calcium fortification in baked goods, beverages, and dairy products.

- Enhances texture and acts as an anti-caking agent.

- Cosmetics and Personal Care

- Used in foundations, powders, and creams to improve texture, absorb oils, and provide a smooth finish.

- Serves as a mild abrasive in toothpaste and exfoliating products.

- Environmental Protection

- Neutralizes acidic wastewater and flue gases in industrial processes.

- Adsorbs heavy metals and pollutants in water treatment applications.

- Agriculture

- Adjusts soil pH and provides calcium nutrients to promote plant growth.

- Enhances the efficacy of pesticides and fertilizers as a carrier material.

- Advanced Ceramics and Composites

- Improves sintering behavior and mechanical strength in ceramic materials.

- Used as a functional filler in high-performance composites for electronics and aerospace.

The versatility of ultrafine calcium carbonate powder stems from its tunable particle size, high purity, and compatibility with diverse matrices, making it a critical material in both traditional and emerging technologies.

Processing of Calcium Carbonate Powder

Calcium carbonate (CaCO₃) powder is produced from natural limestone or marble through a series of mechanical and chemical processes. Below is a simplified overview of the key steps, from raw stone to fine/ultrafine powder:

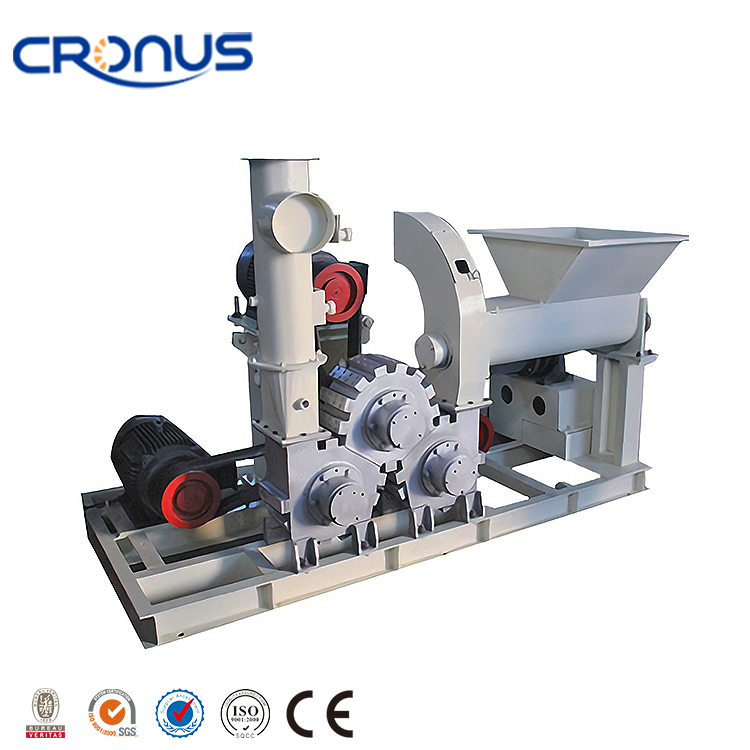

Stone → Crusher → Grinder → Classifier → Ultrafine Mill → Coating Machine → Packaging.

The Raymond mill is a widely used grinding equipment in calcium carbonate processing, offering several key advantages:

- High Efficiency & Energy Savings

- Optimized grinding rollers and ring design ensure high throughput with low energy consumption, ideal for large-scale production.

- Efficient airflow system reduces heat generation, preserving material properties.

- Precise Particle Size Control

- Integrated classifiers allow adjustable fineness (typically 80–325 mesh/180–45 μm) to meet diverse industrial requirements.

- Uniform particle size distribution ensures consistency in end products.

- Cost-Effectiveness

- Lower initial investment and maintenance costs compared to ultrafine grinding systems (e.g., jet mills).

- Durable wear-resistant components minimize downtime and replacement costs.

- Versatility

- Suitable for both dry grinding and processing materials with moderate hardness (Mohs hardness ≤7), including limestone, marble, and calcite.

- Adaptable to varying moisture levels with pre-drying systems.

- Ease of Operation & Maintenance

- Simple structure and automated controls reduce operational complexity.

- Centralized lubrication systems extend equipment lifespan.

- Environmental Compatibility

- Closed-loop dust collection systems minimize airborne particles, ensuring compliance with environmental regulations.

- Scalability

- Modular designs support capacity upgrades for expanding production needs.

Comparison with Other Mills

- Ball Mill: Raymond mills are more energy-efficient for medium-fine grinding.

- Jet Mill: Better suited for ultrafine powders (<10 μm) but at higher operational costs.

The Raymond mill remains a cornerstone in calcium carbonate processing, balancing performance, cost, and flexibility for industries like plastics, coatings, and construction. 🏭

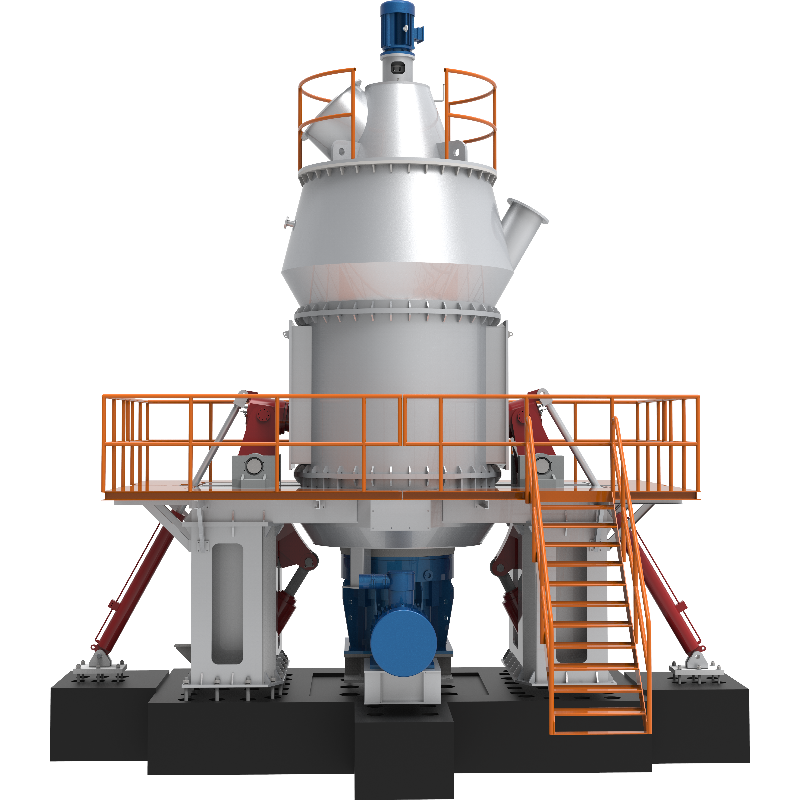

Superfine grinding mills are specifically designed to produce ultrafine powders (typically <10 μm or even submicron level), making them ideal for high-end applications of calcium carbonate. Here are their key advantages:

- Ultrafine Particle Size Control

- Achieve nanometer to micron-level fineness (e.g., 1–10 μm or finer), critical for advanced applications in plastics, coatings, and pharmaceuticals.

- Ensure narrow particle size distribution for enhanced product consistency and performance.

- High Precision and Flexibility

- Advanced classifiers (e.g., dynamic or turbo classifiers) enable precise control over particle size and shape.

- Adjustable parameters (e.g., airflow, grinding pressure) allow customization for diverse material properties.

- Superior Product Quality

- Minimal contamination due to closed-system designs and wear-resistant materials (e.g., ceramic linings).

- Preserve calcium carbonate’s chemical purity and crystalline structure, crucial for food-grade or pharmaceutical uses.

- Energy Efficiency

- Optimized grinding mechanisms (e.g., fluidized bed jet mills, high-pressure roller mills) reduce energy consumption per ton compared to traditional ball mills.

- Efficient particle separation minimizes overgrinding and waste.

- Enhanced Surface Modification Compatibility

- High surface area and reactivity of ultrafine particles improve adhesion to surface modifiers (e.g., stearic acid), boosting compatibility with polymers in composites.

- Scalability and Automation

- Suitable for both small-scale R&D and large-scale industrial production.

- Automated controls and real-time monitoring ensure stable operation and reduced human error.

- Environmental Benefits

- Integrated dust collection systems and low-noise designs meet strict environmental and workplace safety standards.

- Reduced material loss due to efficient recycling of oversize particles.

Comparison with Raymond Mills

While Raymond mills excel in cost-effective medium-fine grinding (45–325 mesh), superfine grinding mills dominate in producing ultrafine/nano powders with superior uniformity and surface properties, catering to high-value industries like electronics, advanced ceramics, and biodegradable materials.

By leveraging these advantages, superfine grinding mills unlock the full potential of calcium carbonate in cutting-edge technologies. 🔬