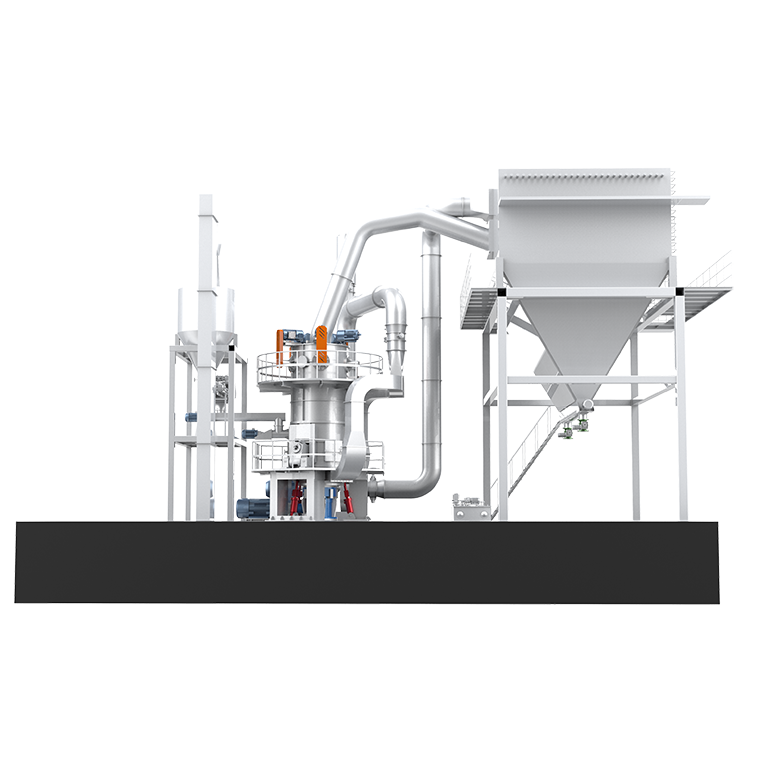

The Slag grinding production line is a kind of equipment used to process slag produced in the industrial production process such as metallurgy, mining, and oil refining. Its main purpose is to process the slag into fine powder for further use. The process flow and equipment configuration of the slag mill production line vary depending on the type and purpose of the slag.

Production Process

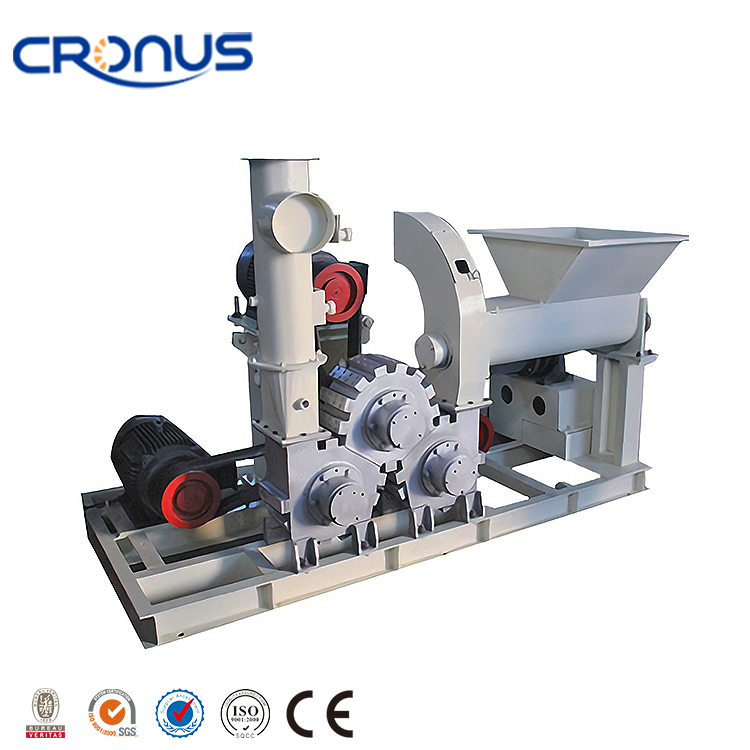

Initial crushing

The slag is first sent to the crusher for initial crushing, which processes it from large bulk materials into smaller particles to prepare for the subsequent grinding process. The purpose of this stage is to reduce the particle size of the slag so that it can be more easily processed by subsequent equipment.

Fine grinding

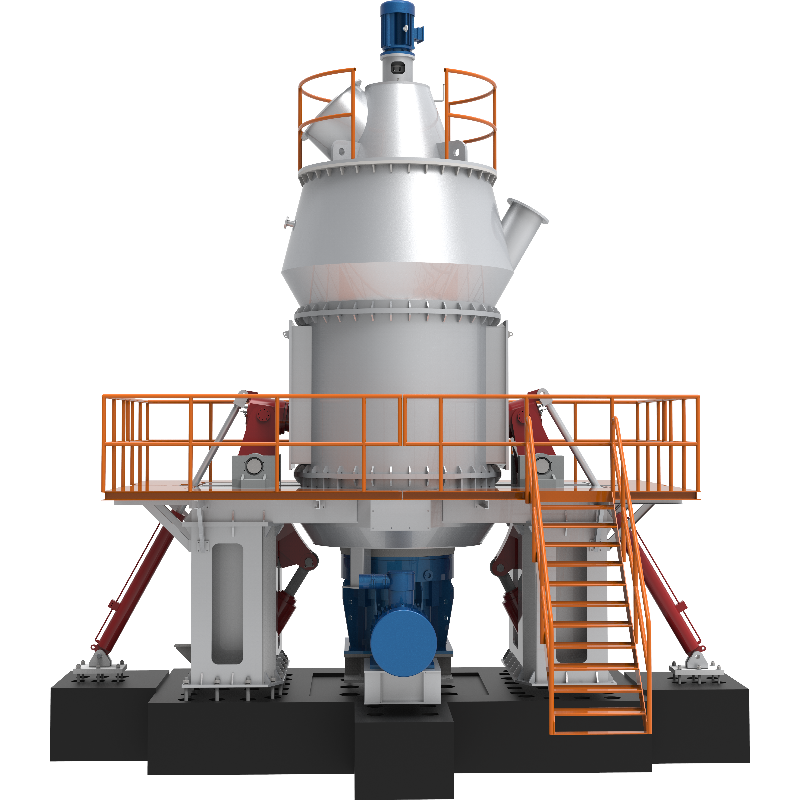

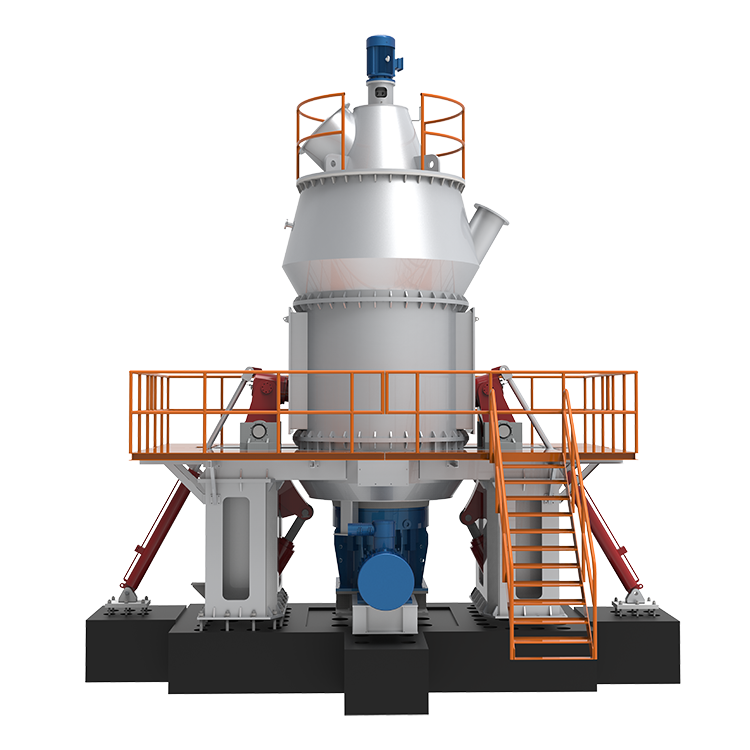

The slag after preliminary crushing is sent to the grinding mill for further fine crushing and grinding. The grinding mill usually adopts vertical mill or Raymond mill, which can grind the slag into fine powder efficiently. Vertical mill is a common equipment, which is characterized by high grinding efficiency, low energy consumption and suitable for large-scale production. During the grinding process, the speed of the grinding mill, the addition of auxiliary materials and other parameters can be adjusted as needed to optimize the grinding effect.

Screening and grading

The ground slag powder needs to be graded by screening equipment to ensure that the particle size of the powder meets the requirements. The fine powder after screening can be used for specific purposes, such as building materials or industrial raw materials, while the larger particles are returned to the mill for further processing.

Packaging and storage

The screened slag powder is packed into storage bags for easy transportation and sales. This process requires strict environmental control to avoid dust pollution

Main uses

Building materials: Slag can be used as a component of building materials, such as high-performance cement, concrete, bricks, roadbed fillers, etc. The application of slag in building materials can improve the strength and durability of materials, reduce the cost of materials and the impact on the environment.

Agricultural uses: Slag can be used as a soil conditioner to improve soil quality, increase soil fertility and water retention capacity, etc. In addition, slag contains certain trace elements that can promote plant growth.

Industrial raw materials: Slag contains a large number of useful elements or compounds, such as iron, aluminum, potassium, silicon, etc., and can be used as industrial raw materials to produce other products, such as iron, aluminum, silicates, etc.

Environmental governance: Slag can be used in sewage treatment, waste gas purification and waste treatment, and can adsorb, precipitate or dissolve harmful substances in wastewater, waste gas and waste residue, thereby reducing pollution and damage to the environment.