As the core equipment of modern industrial powder processing, Raymond mill has shown irreplaceable value in the field of marble deep processing with its efficient and precise grinding ability. Marble has become an important raw material in the construction, decoration, chemical and other industries with its unique texture, stable physical and chemical properties and wide application scenarios.

Raymond mill and marble

Raymond mill can convert ore raw materials into fine powder and play an important role in non-metallic mineral processing. Whether it is limestone, kaolin or marble, Raymond mill can grind it into fine powder that meets industrial needs and is a key equipment in industrial production lines.

Marble has a Mohs hardness of 3-4, which belongs to medium and low hardness ore. It is easy to process with Raymond mill, with high grinding efficiency and small equipment wear. Its main component is calcium carbonate, which has stable chemical properties and is not easy to change during the grinding process, ensuring the purity and quality of the product.

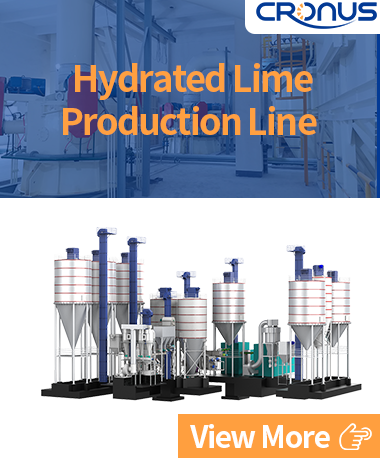

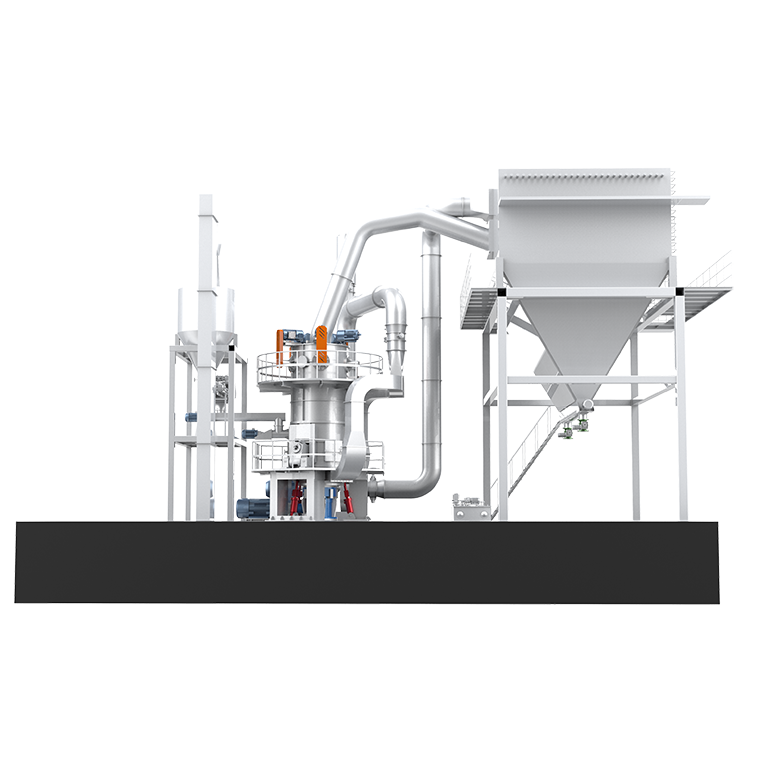

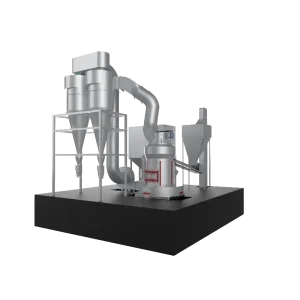

Analysis of the marble processing process of Raymond mill

Raw material preparation: Use a crusher to crush the marble into small pieces and send it to the storage bin through an elevator.

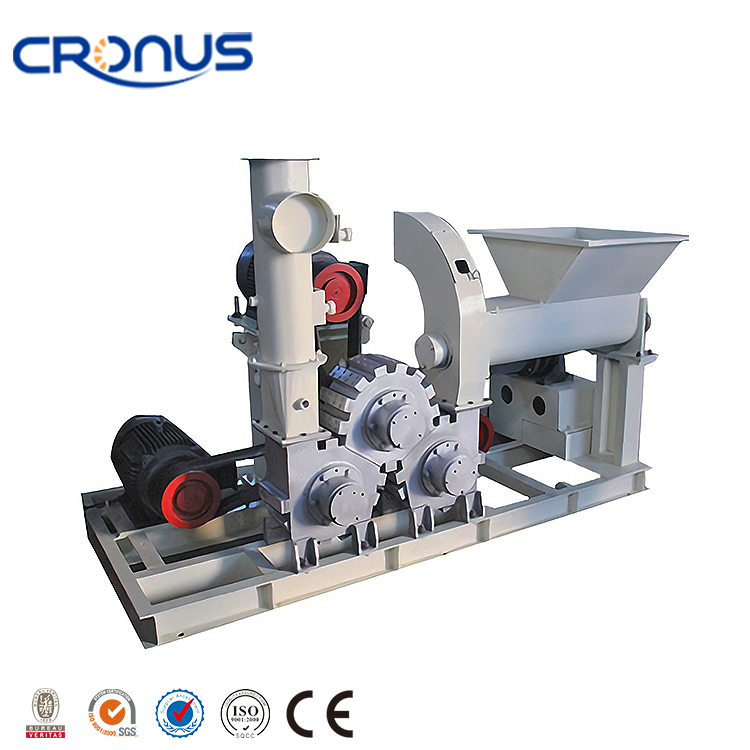

Grinding: Small pieces of marble enter the Raymond mill, and the grinding roller and grinding ring rotate and grind under the drive of the motor to gradually crush the marble into powder.

Classification: The analyzer classifies and screens the ground marble powder, the coarse particles return to the main machine for grinding, and the fine powder enters the next step.

Collection: Qualified fine powder enters the cyclone collector with the air flow, and the fine powder is separated by centrifugal force, and then collected and discharged as the final product. A small amount of fine dust is purified by a pulse dust collector to ensure environmentally friendly emissions.

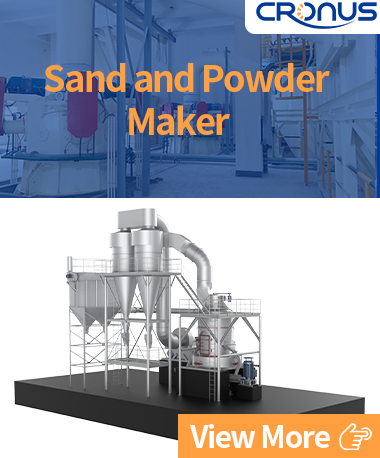

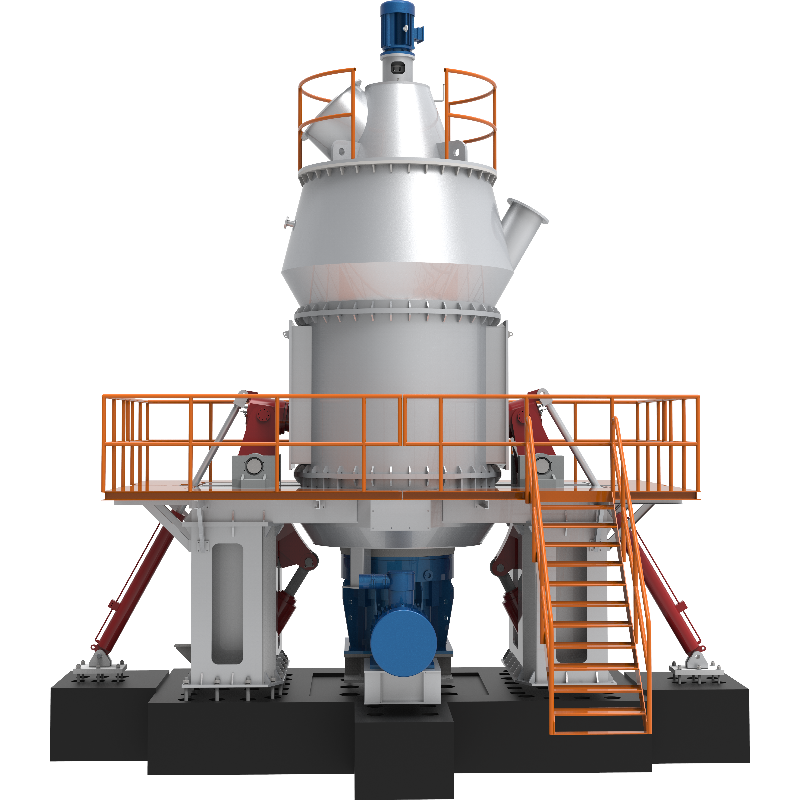

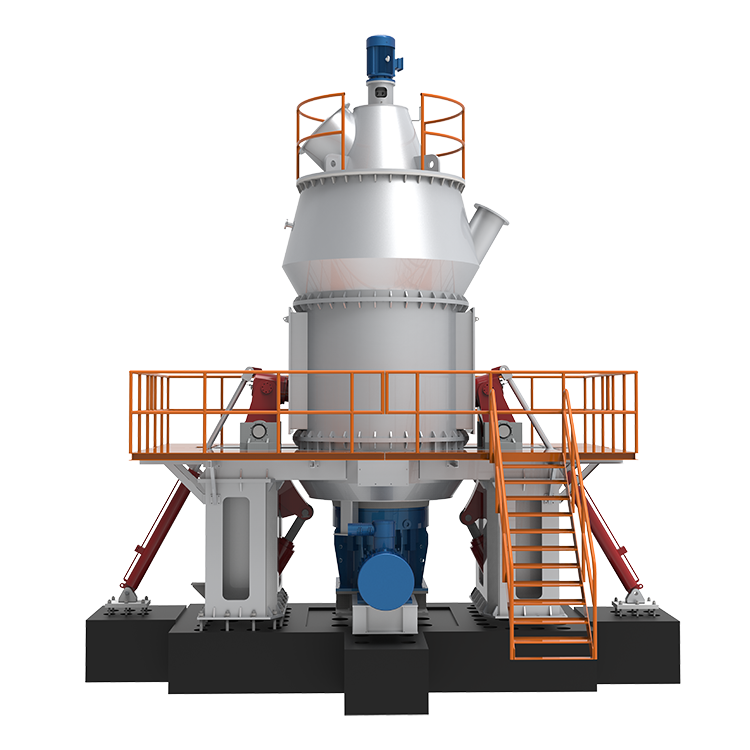

Raymond mill selection

Set parameters according to fineness: Raymond mill can produce marble powder from 80 mesh to 325 mesh or finer. The appropriate fineness needs to be determined according to the application scenario to ensure precise control of the grading system.

Choose power to match the scale: large models are equipped with high-power motors to ensure high efficiency, small models avoid high power to prevent waste, and match as needed.

Durability selection material: grinding rollers and grinding rings are selected from wear-resistant materials such as high manganese steel and special alloys, and the frame, conveyor belt, etc. are also of high quality to ensure the durability and stability of the equipment.

High-value application scenarios of marble powder

Green building materials field

Modified concrete: Adding 10%-15% marble powder can increase the compressive strength by 12% and reduce the amount of cement.

Environmentally friendly coatings: As a functional filler, it enhances the weather resistance and suspension stability of the coating.

High-end decorative materials

Artificial quartz stone: Marble powder accounts for 40%-60%, replicating the texture of natural stone and reducing costs by 35%.

New chemical materials

Degradable plastics: The calcium carbonate filling ratio reaches 20%-30%, which meets the EU degradation standards

If you are looking for a Raymond mill with excellent performance and reliable quality, Cronus is your ideal choice. Cronus focuses on the research and development and manufacturing of Raymond mills. With advanced technology, strict processes and considerate services, we can create Raymond mill equipment that meets various needs for you, helping you stand out in the industry competition. Contact Cronus now to start a new journey of efficient production and work together to create a brilliant future.