Pyrophyllite

Pyrophyllite (Talc) is a soft rock with the chemical formula Mg3Si4O102. It is mainly composed of magnesium, silicon, oxygen and hydrogen elements. Its physical properties are very stable and it is a mineral with a special slippery feel. Pyrophyllite is a very soft mineral with a hardness of only 1, making it one of the […]

- Processing Material:

- Output:

- Feed Particle Size:

- Discharge Particle Size:

Pyrophyllite (Talc) is a soft rock with the chemical formula Mg3Si4O102. It is mainly composed of magnesium, silicon, oxygen and hydrogen elements. Its physical properties are very stable and it is a mineral with a special slippery feel.

Pyrophyllite is a very soft mineral with a hardness of only 1, making it one of the softest minerals. Due to its excellent lubricity, it is widely used in cosmetics, food, pharmaceuticals, plastics, rubber, ceramics and other industries, and can be used as filler, lubricant, anti-sticking agent, waterproofing agent, etc. In addition, pyrophyllite can also be used to make graphene, polymer composites, flame retardant materials, etc. Pyrophyllite can also be used as a high-temperature ceramic material and is widely used in the manufacture of refractory materials, ceramics, glass, etc.

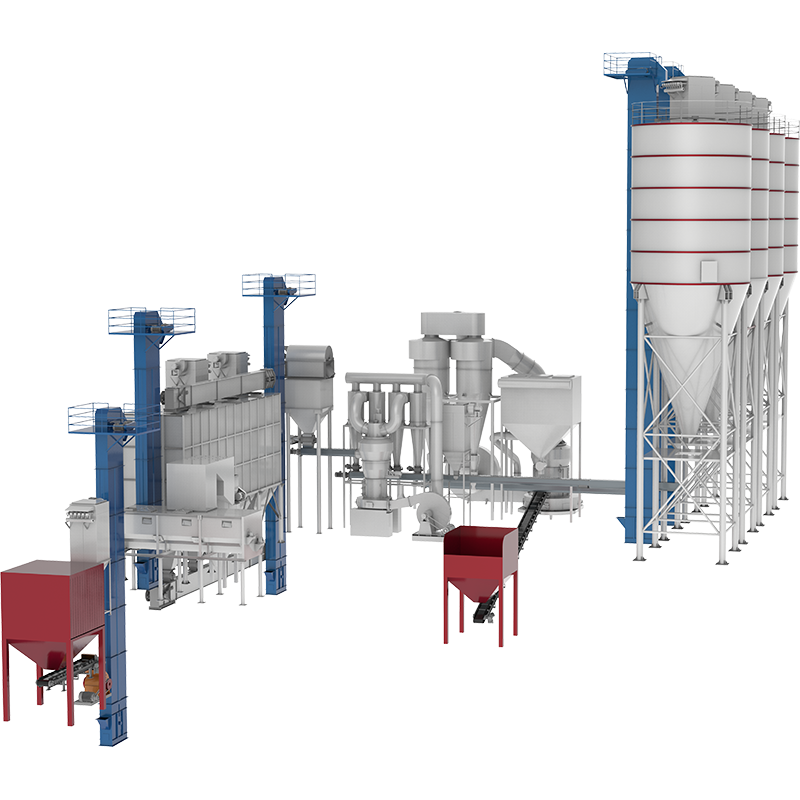

Process Flow

Stage One: Grushing

Usually, the jaw crusher or hammer crusher is used to initially crush the pyrophyllite raw materials into appropriate particle sizes.

Stage Two: Grinding

Pyrophyllite particles that have been initially crush usually require further grinding. This process can be carried out through equipment such as ball mills and pulverizers.

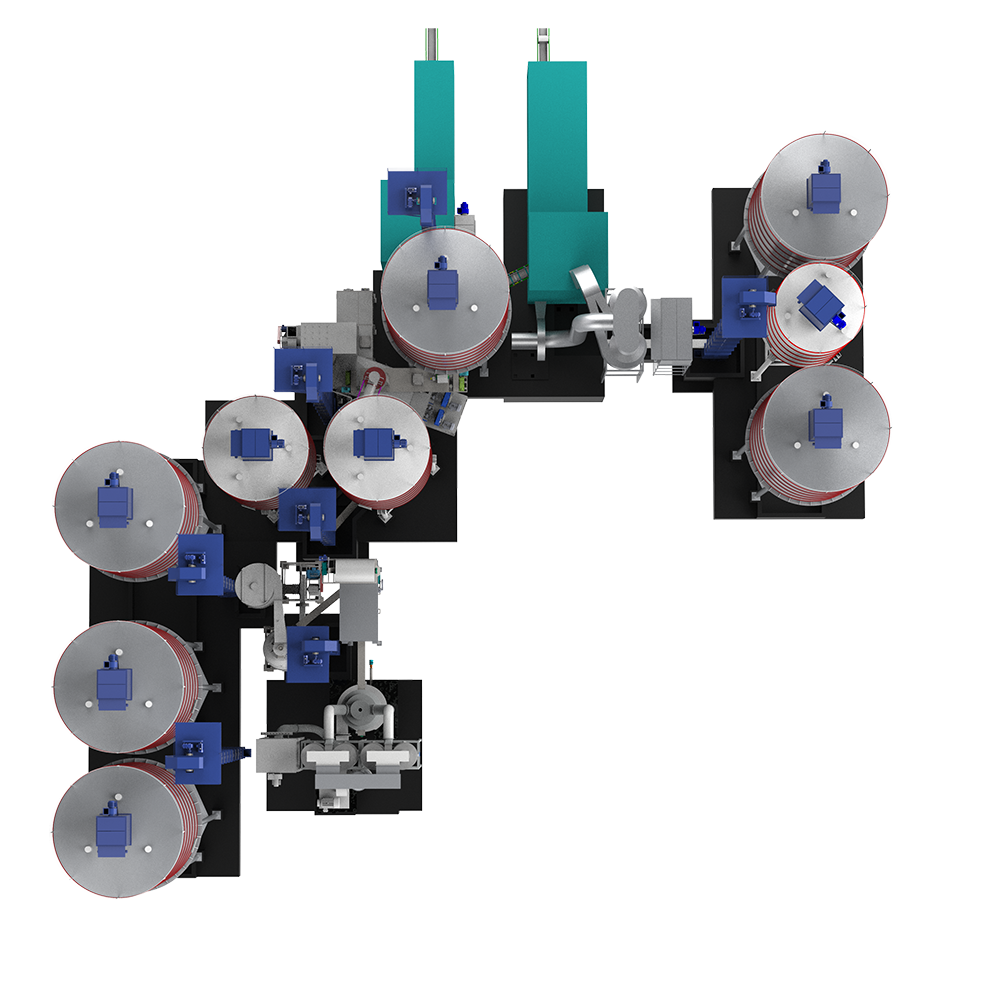

Stage Three: Classifier

The ground pyrophyllite powder is classified through screening equipment to obtain the required particle size.

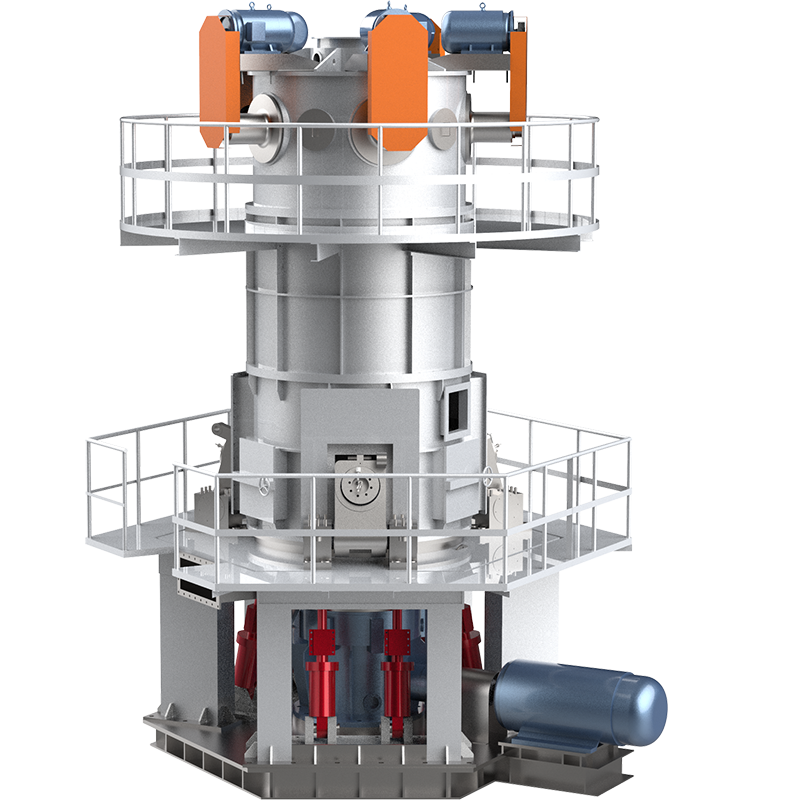

Stage Four: Precision Grinding

The initially grinding pyrophyllite powder is finely grind to obtain a finer powder. This process can be carried out through equipment such as ultra-fine mills and flying classifiers.

Stage Five :Dust Collection

In order to ensure product quality and production environment, the finely grinding pyrophyllite powder needs to be dusted to remove impurities and dust.

Stage Six: Packing

The pyrophyllite powder after the above processing needs to be packaged, usually in bags, barrels, bulk, etc., and must be labeled, stored, etc.

The Main Purpose

- Plastic and rubber filler: Pyrophyllite has good chemical stability and plasticizing properties and can be used as a filler in plastics and rubber to improve the hardness, strength and wear resistance of the material.

- Paints and coatings: Pyrophyllite has good whiteness, gloss and hiding properties and can be used as a white pigment in paints and coatings.

- Papermaking industry: Pyrophyllite can be used in the papermaking industry as filler and coating to improve the gloss, whiteness and smoothness of paper.

- Cosmetics: Pyrophyllite can be used in cosmetics as a gloss and filler to improve the appearance and texture of the product.

- Pharmaceutical industry: Pyrophyllite can be used in the pharmaceutical industry as a drug carrier and stabilizer to improve the stability and bioavailability of drugs.

- Other industrial applications: Pyrophyllite can also be used in rubber products, paints, ceramics, glass, plastics, textiles, building materials and other fields.