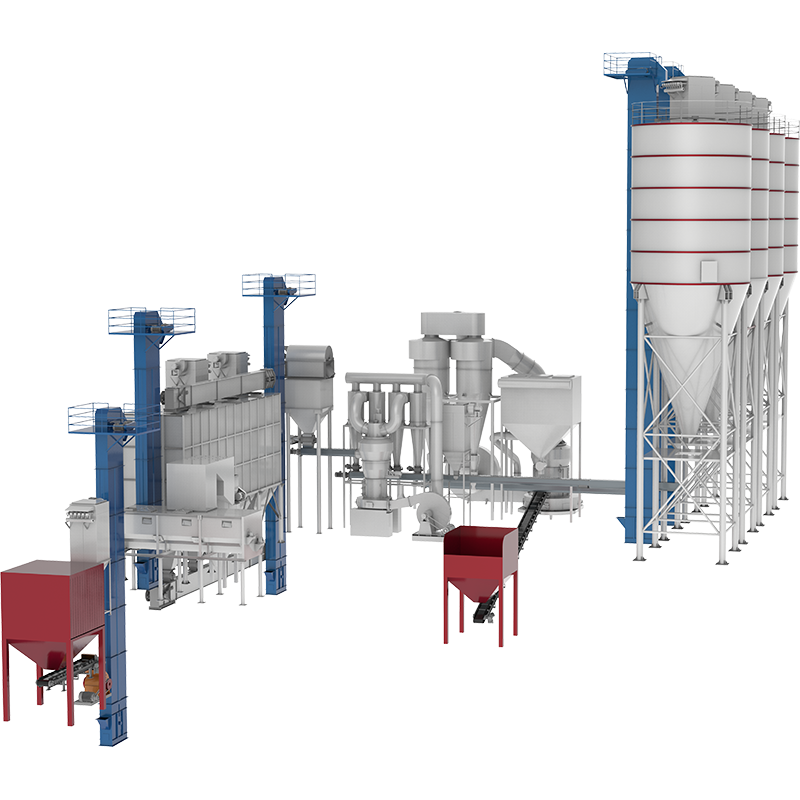

Raymond Mill is a classic grinding equipment widely used in industries such as mineral processing, building materials, chemicals, and metallurgy. It is particularly suitable for crushing and processing materials with medium to low hardness. Due to its simple structure, user-friendly operation, and high efficiency, Raymond Mill is extensively utilized. Below is professional knowledge about Raymond Mill, including its working principles, structural features, application areas, and maintenance.

1. Introduction to the Working Principles of Raymond Mill

The working principle of Raymond Mill is based on the crushing of materials through high-pressure compression and shear forces between the grinding rollers and the grinding ring. The specific process is as follows:

- Feeding System: Materials are fed into the grinding chamber of the mill through a feeding device.

- Grinding Process: Under centrifugal force, materials are pressed by the grinding rollers against the grinding ring, where they are crushed into fine powder through strong rolling and shearing actions.

- Classification System: The crushed materials are carried by airflow to the classifier, which adjusts the particle size by controlling its rotational speed to ensure the powder reaches the desired fineness.

- Collection System: The crushed materials are collected by a cyclone separator or bag filter, with fine powder being output and coarse particles returned to the mill for re-grinding.

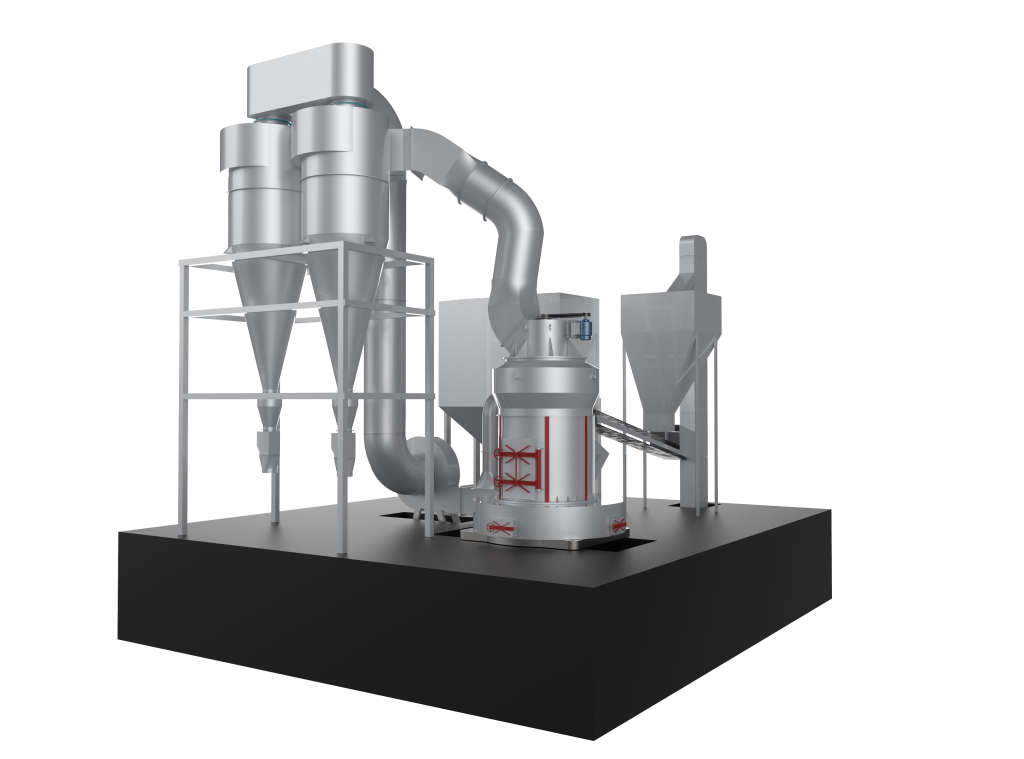

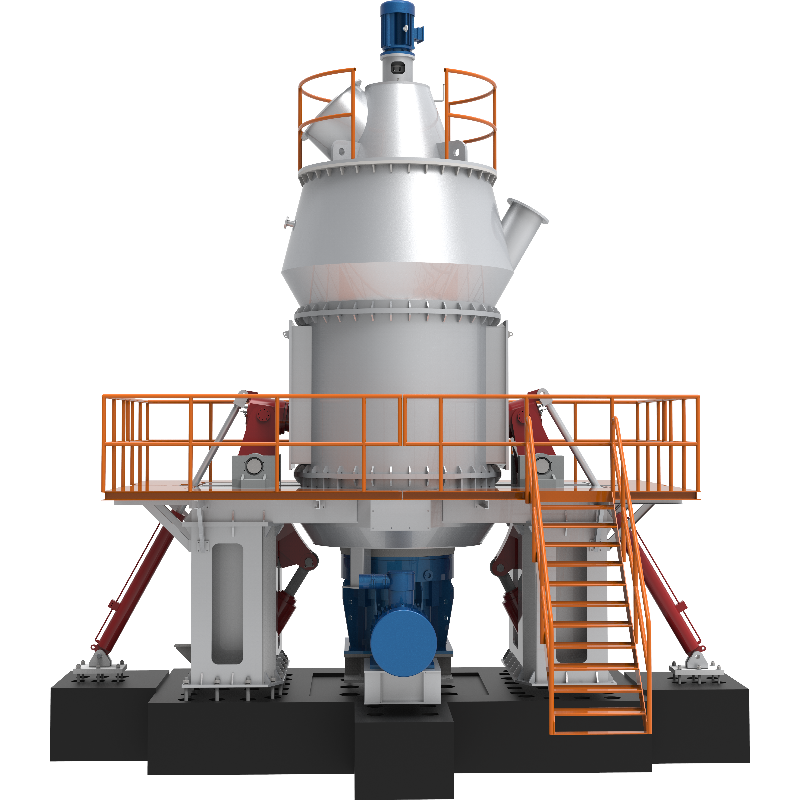

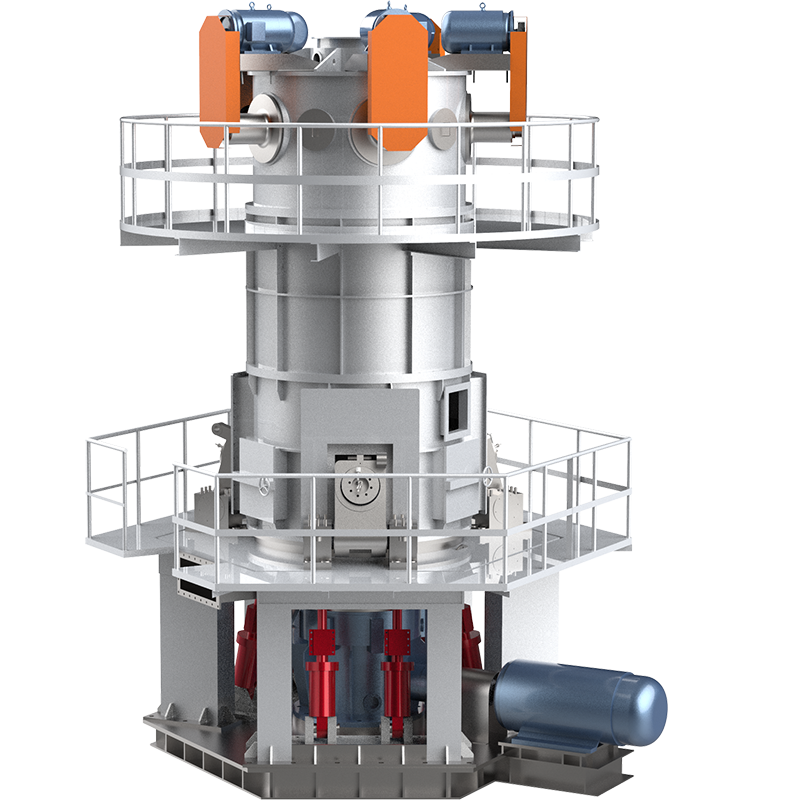

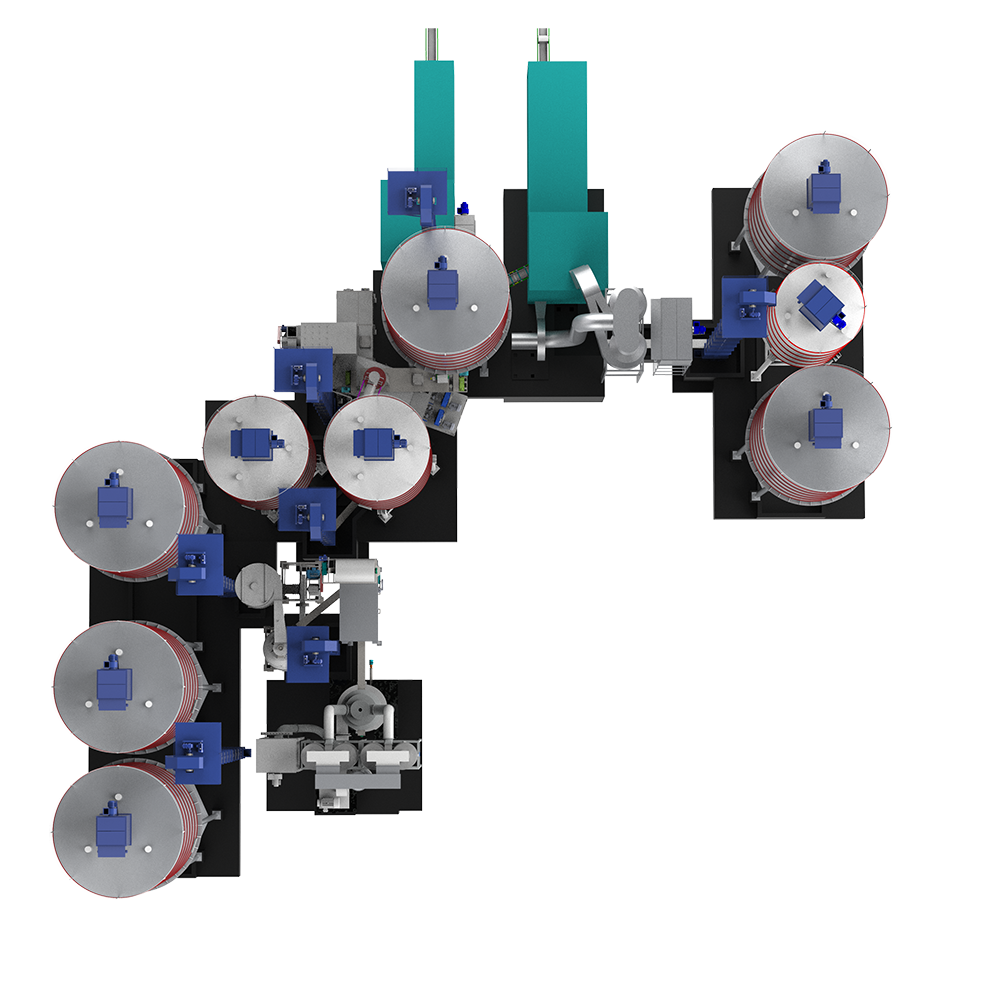

2. Main Structural Components of Raymond Mill

The main structural components of Raymond Mill include:

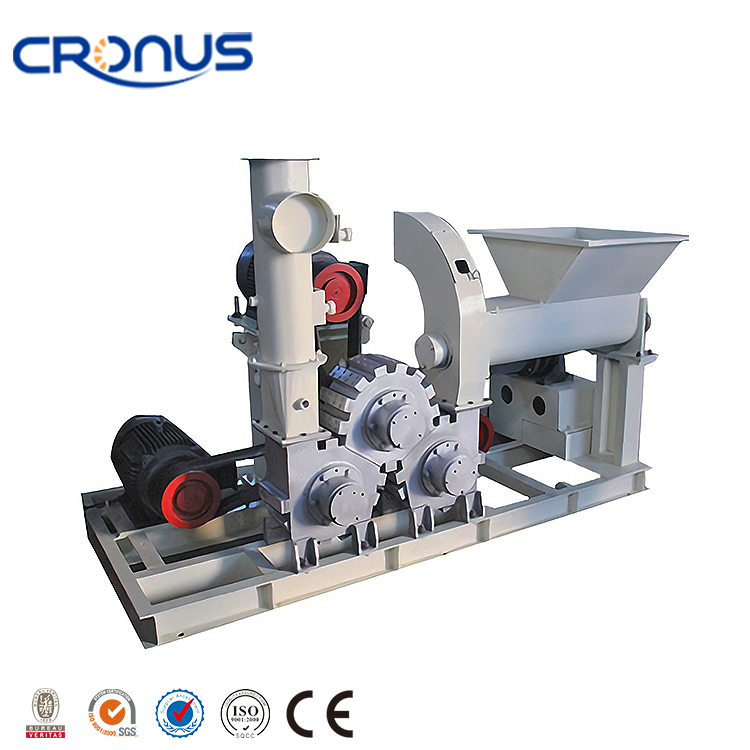

- Grinding Rollers and Grinding Ring: These are the core components responsible for material crushing. The number of rollers and the design of the grinding ring directly affect the crushing efficiency and particle size distribution.

- Main Machine: Composed of grinding rollers, grinding rings, and transmission devices, the main machine provides the mechanical force for material crushing.

- Classifier: Adjusts the particle size of materials by controlling the rotational speed of the classifier to precisely control the fineness of the final product.

- Blower: Provides airflow to assist in transporting materials to the classifier and maintains airflow circulation within the grinding chamber.

- Dust Collection System: Includes a cyclone separator and bag filter, used to recover fine powder and reduce dust emissions, meeting environmental standards.

3. Technical Features of Raymond Mill

Raymond Mill has the following technical features:

- High-Efficiency Grinding: The high-pressure grinding roller system ensures efficient material crushing through centrifugal and pressure forces.

- Adjustable Particle Size: By adjusting the rotational speed of the classifier, the fineness of the final powder can be precisely controlled, typically processing materials ranging from 30 to 400 mesh.

- Energy-Saving and Eco-Friendly: The equipment is designed with a rational structure, low energy consumption, and minimal dust emissions, meeting environmental requirements.

- Easy Maintenance: Its simple structure makes it easy to operate and maintain, reducing downtime.

- Strong Adaptability: Raymond Mill can process a wide range of materials, from common minerals to special materials, with effective crushing results.

4. Application Areas of Raymond Mill

Raymond Mill is widely used in the following industries:

- Mineral Processing: Crushing minerals such as limestone, calcite, talc, barite, quartz, and bentonite, suitable for cement, building materials, and glass production.

- Building Materials Industry: In cement production, concrete preparation, and brick manufacturing, Raymond Mill effectively improves the fineness of raw materials, enhancing product performance.

- Chemical Industry: Used to produce chemical products such as calcium carbonate, silicates, and titanium dioxide, widely applied in coatings, plastics, and rubber industries.

- Metallurgical Industry: Crushing iron ore, bauxite, and titanium ore for metal smelting and refining.

- Environmental Industry: Processing waste materials such as fly ash, steel slag, and mineral slag to promote resource utilization.

- Food and Pharmaceutical Industry: Processing starch, pharmaceutical raw materials, and especially producing ultrafine powder to improve drug solubility and bioavailability.

5. Advantages of Raymond Mill

Advantages:

- High Efficiency: The precise coordination of grinding rollers and rings ensures high crushing efficiency, suitable for large-scale industrial production.

- Adjustable Particle Size: By adjusting the classifier speed, the fineness of the powder can be precisely controlled to meet the production needs of different industries.

- Energy-Saving and Eco-Friendly: The rational design of Raymond Mill ensures high energy efficiency, low energy consumption, and minimal dust emissions.

- Easy Operation: Its simple structure makes it easy to operate and maintain.

6. Operation and Maintenance of Raymond Mill

Operation:

- Check the feeding equipment to ensure it is functioning properly and avoid overfeeding, which may cause blockages.

- Inspect the operation status of the main machine, blower, and classifier to ensure they are working normally.

Maintenance:

- Regularly check the wear of grinding rollers and rings, and replace worn parts promptly to ensure crushing efficiency.

- Inspect the operation of the classifier to ensure its rotational speed is within a reasonable range, avoiding uneven particle size distribution.

- Keep the equipment clean, regularly check the lubrication system, and ensure the lubricant is sufficient and clean.

- Regularly clean the dust collection system to prevent dust accumulation and system blockages.

Raymond Mill is a highly efficient grinding equipment widely used in mineral processing, building materials, chemicals, metallurgy, and other fields. Its simple structure, high crushing efficiency, and low energy consumption make it an essential grinding device in industrial production. Understanding the working principles, structural features, and operation and maintenance points of Raymond Mill will help improve equipment efficiency and production benefits.