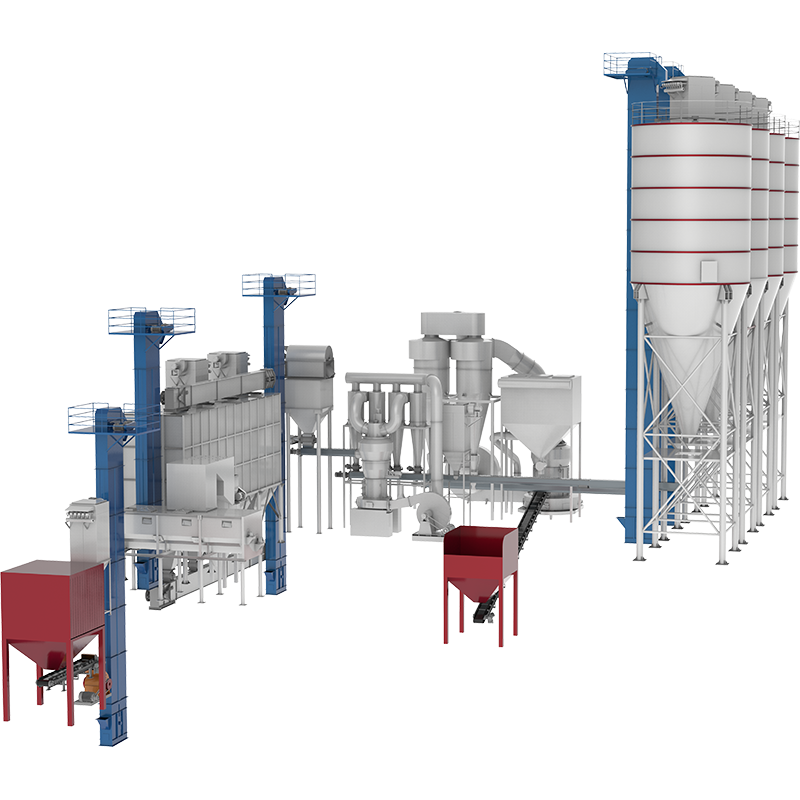

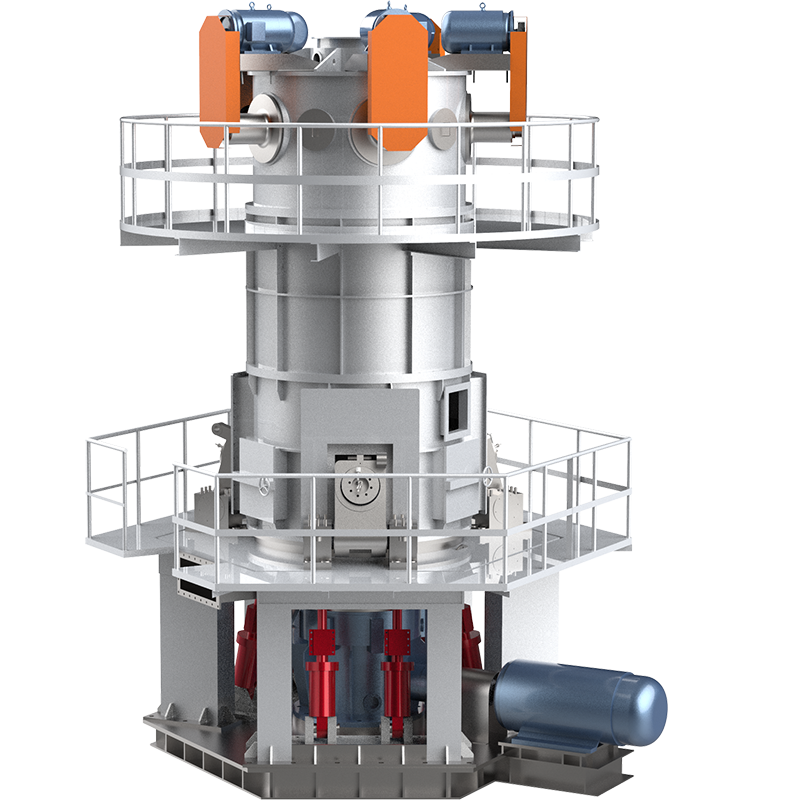

Hydrated Lime Production Line-CRQ series Lime Slaker

Application Range The is mainly used in metallurgy, construction, medicine, food, sugar and chemical industries, papermaking, feed additives, fertilizer agriculture, petroleum additives, waste incineration flue gas treatment, sewage treatment Hydrated lime has a variety of industrial applications like water treatment, building, waste gas treatment soil stabilization, etc. Notice: JavaScript is required for this content.