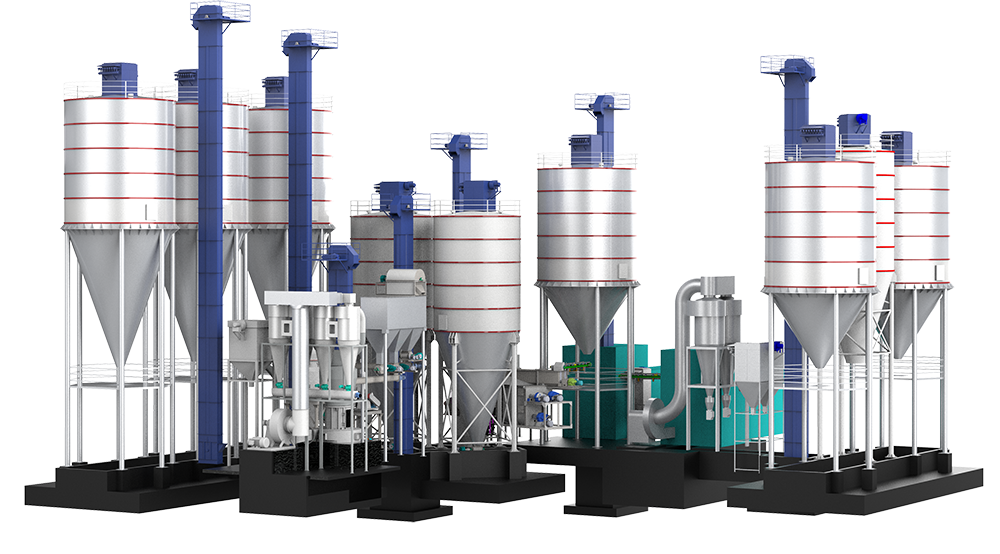

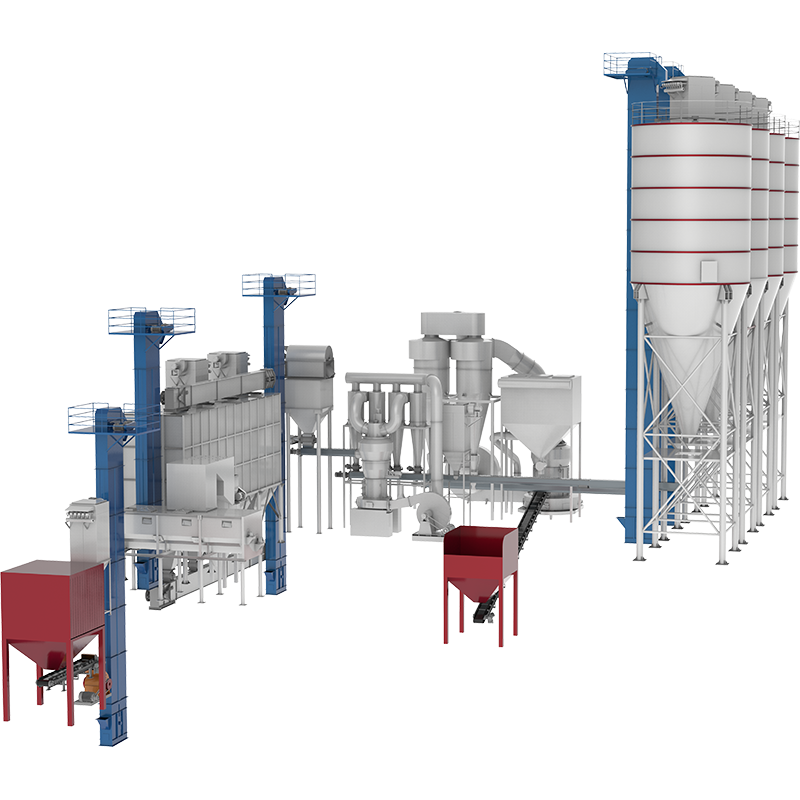

Hydrated Lime Production Line

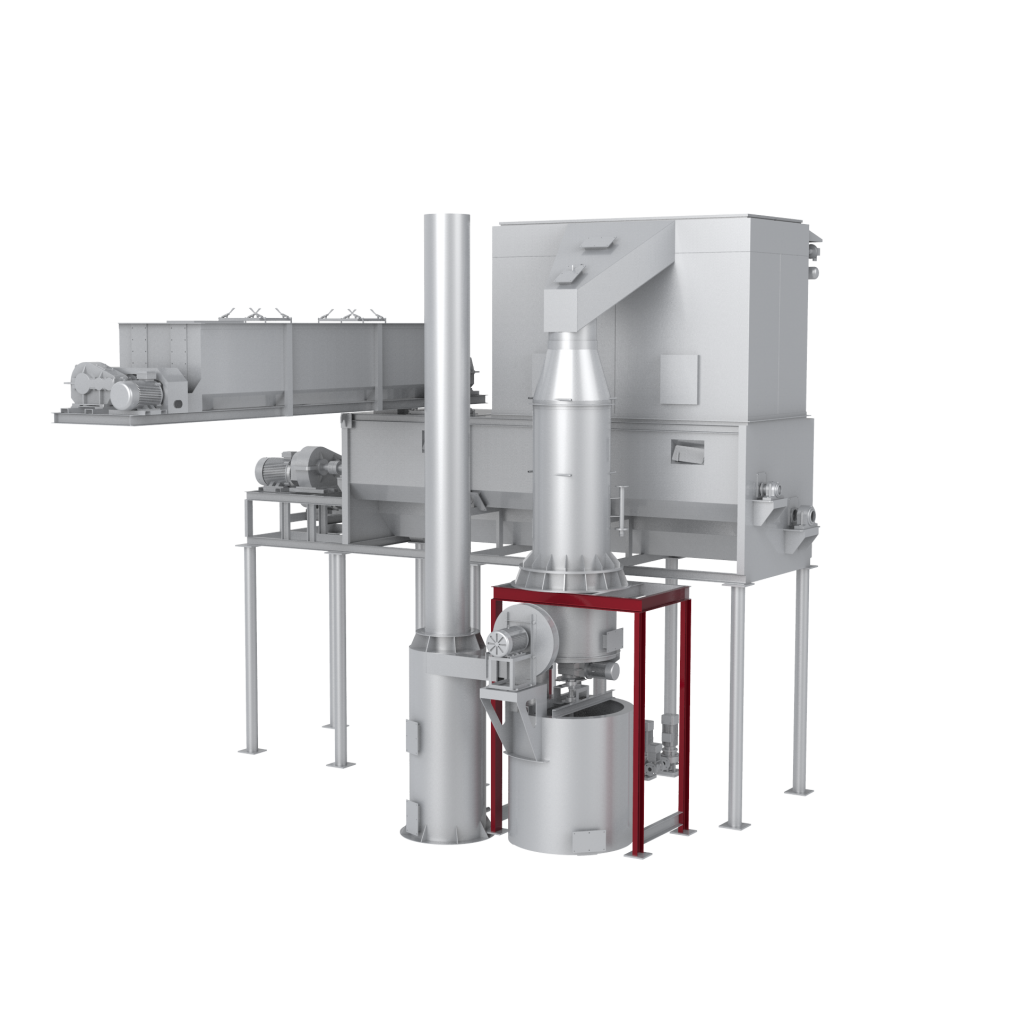

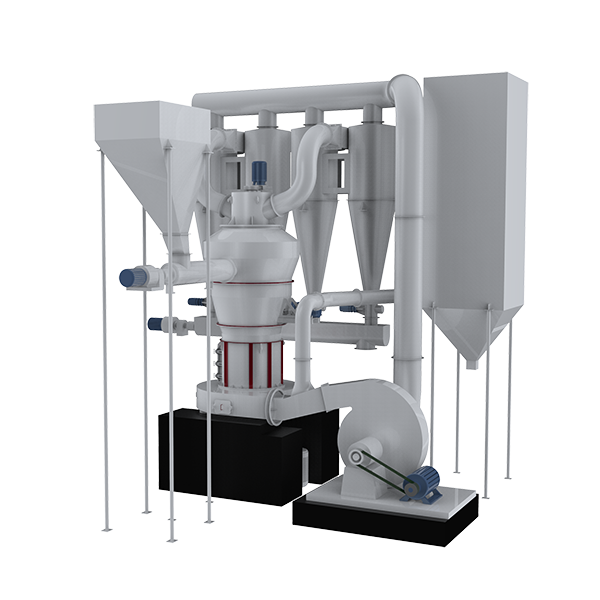

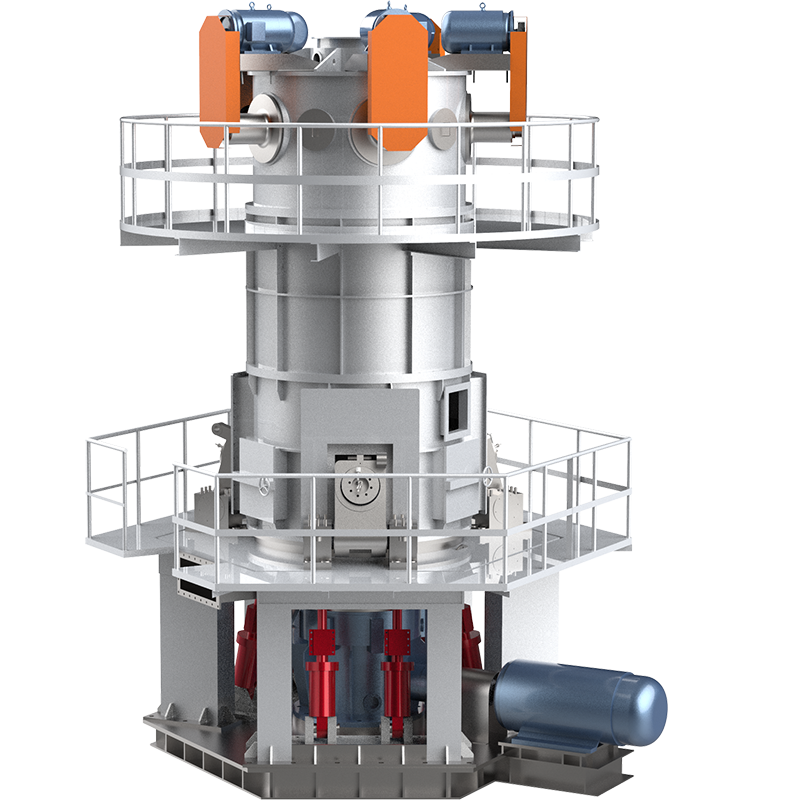

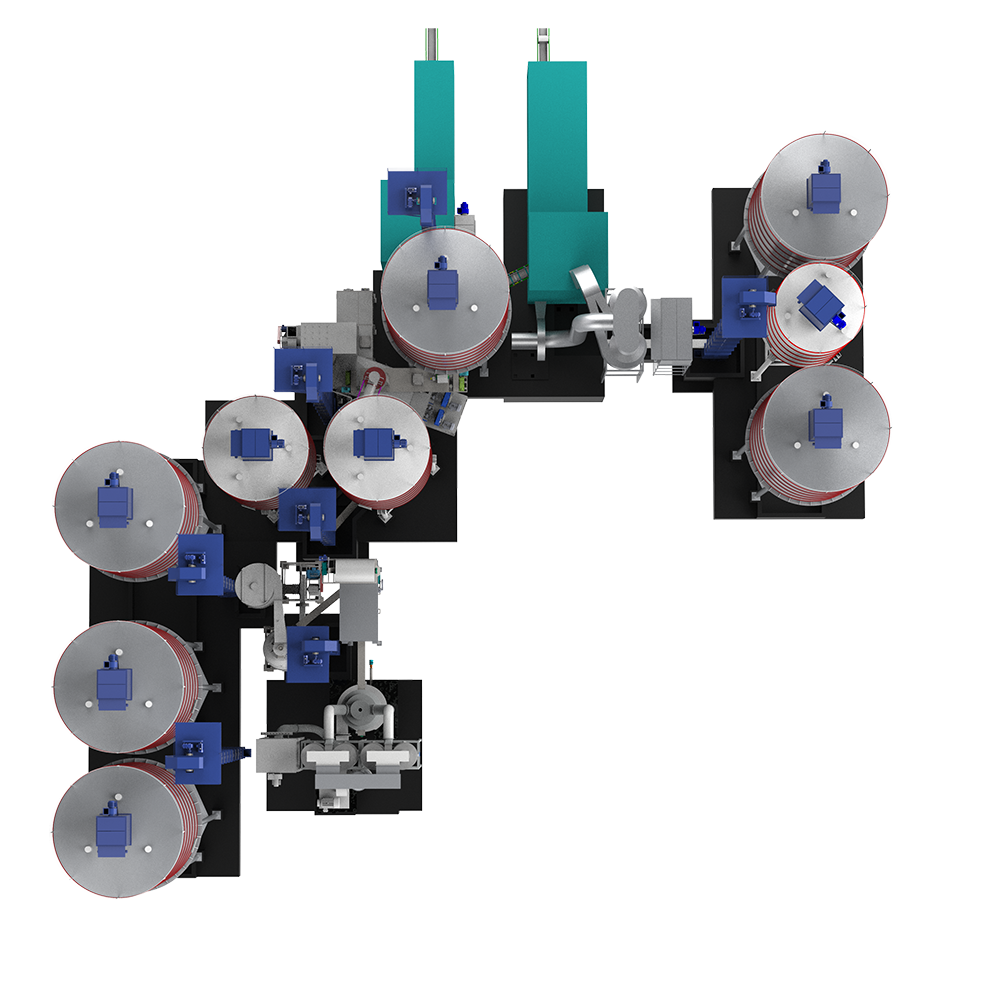

CRQ calcium hydroxide production line is Cronus to explore the lime industry and kiln deep processing development direction, after many tests and improvements, the successful development of lime deep processing technology and equipment. The whole production line is mainly composed of CRS lime slaker, CRLM calcium hydroxide special grinding machine, a fine powder separator with […]