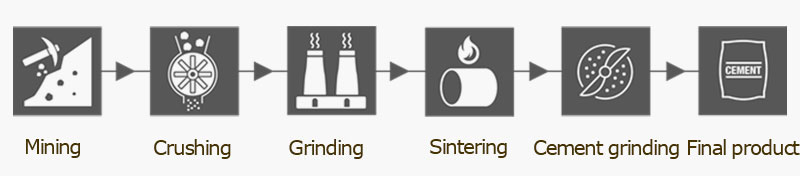

Limestone is the most critical raw material in cement production and its use runs through the entire cement manufacturing process.

How is limestone used to make cement?

Limestone Mining

Cement manufacturing begins with the mining of raw materials, mainly limestone and clay. Limestone is usually mined in open pits. There are some underground limestone mines, but most are above ground pits.

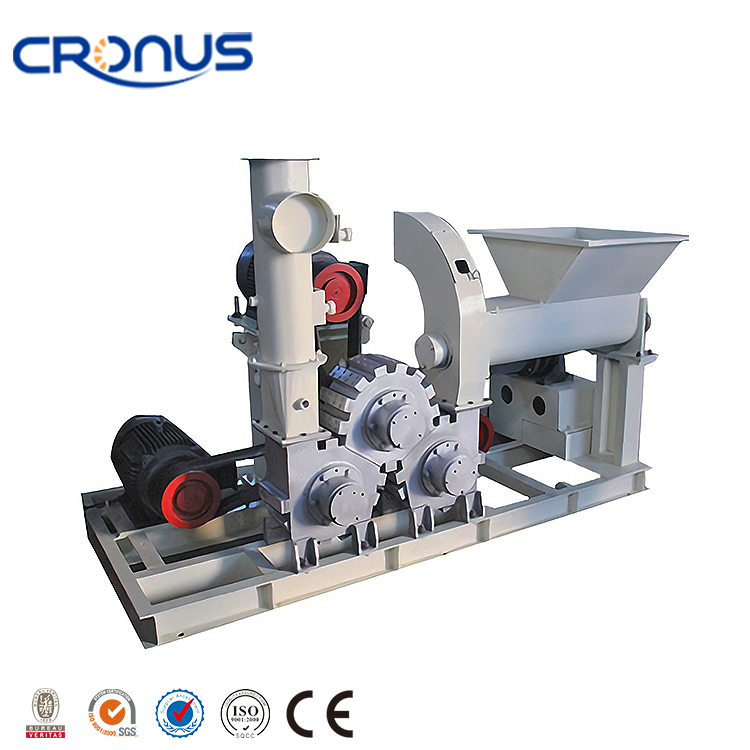

Limestone Crushing

Most of the limestone mined by blasting in the mines is large in size, so it is necessary to use a limestone crusher to break it into uniform small pieces or particles for homogenization and subsequent calcination and grinding.

Most cement plants use jaw crushers for primary crushing and hammer crushers and impact crushers for secondary crushing.

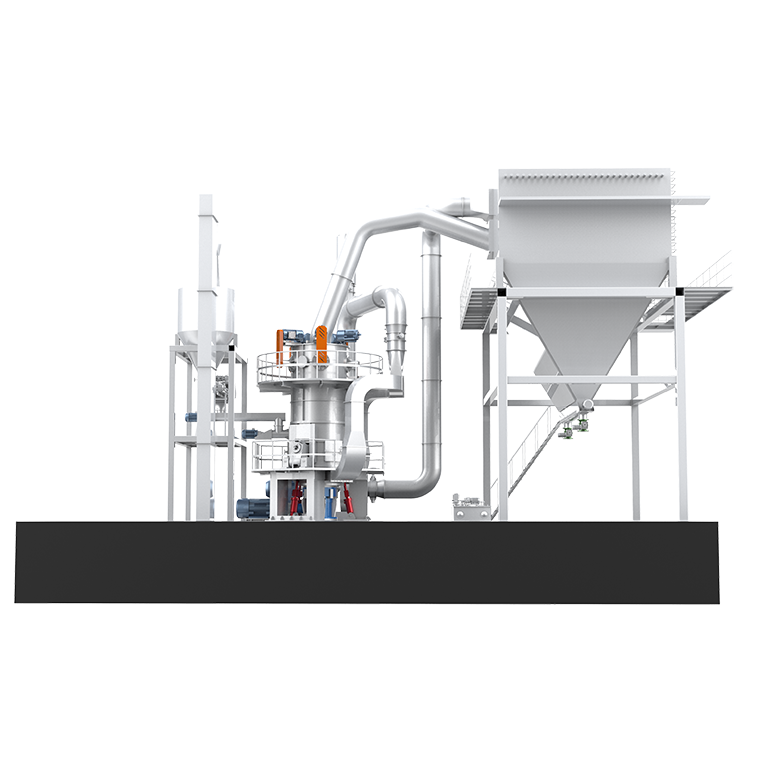

Cement raw material homogenization and fine grinding

The cement raw materials (limestone, clay, etc.) are sent to the batching station for homogenization, and then the homogenized raw materials are sent to a ball mill for fine grinding according to a certain feeding amount to obtain raw meals.

Clinker Calcination

The raw material is fed into a cement kiln where it is heated to a sintering temperature of up to 1450 degrees Celsius. During this process, the chemical bonds of the raw materials are broken and then recombined into new compounds. The final product is called clinker and is a rounded ball with a diameter between 1 mm and 25 mm.

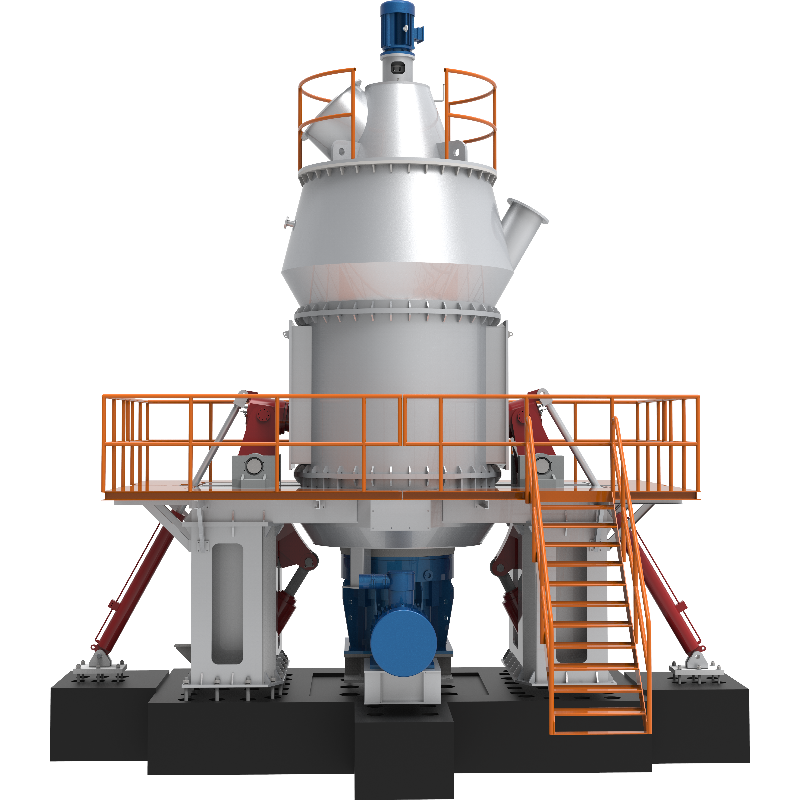

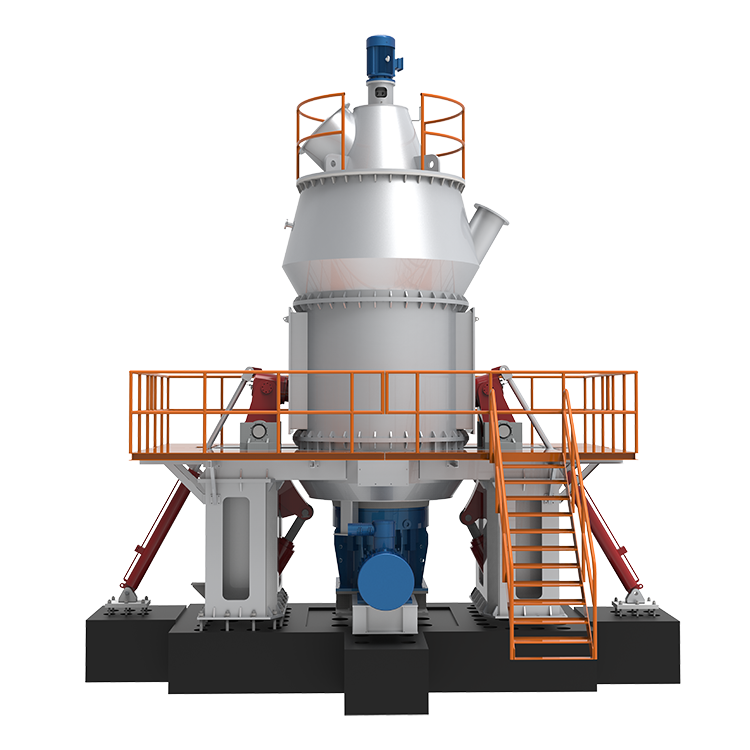

Cement Grinding

After mixing with gypsum and admixtures, the clinker is sent to cement mill for grinding. Cement grinding can be done in integrated cement plants or stand-alone cement plants. Cement Grinding Plant.