Dolomite is an important calcium and magnesium resource on the earth, and it has extremely rich reserves in CHINA. The main production areas are Shandong, Liaoning, Shanxi, Hebei and the two lakes. Dolomite is mainly composed of carbonate rocks with dolomite (CaMg (CO3) 2) as the main component. During the formation process, due to the influence of different geological actions and environments, it is often mixed with some impurities such as calcite, clay minerals, flint, magnesite, etc., and sometimes contains gypsum, anhydrite, celestite, barite, pyrite and organic matter. It is a non-metallic mineral with a very wide range of uses.

Development and application of dolomite ore series products

Metallurgical industry

Magnesium smelting industry

Dolomite with a particle size of 30-120mm is a key raw material for magnesium production, primarily through electrolysis and silicon thermal reduction. Electrolysis is complex, costly, and environmentally challenging due to chlorine by-products, making it suitable only for large-scale operations. In contrast, the silicon thermal reduction method, including the semi-continuous, internal heat, and Pijiang methods, is more commonly used in China, contributing to 20% of magnesium production. The Pijiang method involves calcining dolomite, mixing it with ferrosilicon and fluorite, heating it in a vacuum furnace at 1100℃ to produce magnesium vapor, which is then cooled and cast into ingots. The efficiency of this method depends on the activity of calcined dolomite, influenced by factors like MgO, CaO, and SiO2 content, roasting temperature, time, and storage duration.

Refractory materials

As one of the important raw materials for alkaline refractory materials, dolomite is second only to magnesite in importance. It is mainly used for steelmaking converter linings, open-hearth furnaces, electric furnace walls, and secondly for thermal equipment such as external refining devices and cement kilns.

Dolomite can be used to make dolomite brick series (currently mainly conventional dolomite bricks, zirconium-enhanced dolomite bricks, zirconium-enhanced magnesium dolomite bricks, etc.), fused dolomite carbon bricks and fused magnesium dolomite carbon bricks. The results of the latter two show that the fused dolomite carbon bricks are better than the sintered magnesium dolomite carbon bricks, and are similar to the level of magnesium carbon bricks. In addition, when using tar dolomite bricks made by calcining high-purity dolomite with iron ore as furnace linings, the method of spraying dolomite spraying materials can significantly increase the life of the furnace. For example, Japan uses the method of gunning to increase the furnace life to several thousand to ten thousand furnaces, while large furnaces consume 25 to 50 thousand tons of gunning grade dolomite each year. In cement rotary kilns, dolomite brick series are more suitable for high-temperature sintering belt linings compared with magnesia spinel bricks and magnesia chrome bricks. However, as a refractory material, dolomite bricks are easily hydrated, which affects their dosage and performance. Therefore, in sand making and brick making, processes that are conducive to improving hydration resistance are often used, such as two-step calcination, and mechanical and additive activation methods are used to produce dolomite sand with low sintering temperature and high density. Therefore, the current sand making process is developing towards electric melting, high-purity sintered sand and synthetic sand.

In addition, the hydration resistance of fired direct-bonded dolomite bricks is 4 times higher than that of asphalt-bonded bricks, and the hydration resistance of fired bricks can be further improved after asphalt impregnation.

Ironmaking blast furnace plugging material

Wuhan Iron and Steel Corporation once used dolomite with a raw ore particle size of 0-30 mm directly as a plugging material for molten iron holes in blast furnaces. If 0-30 mm dolomite is burned white as a plugging material for molten iron holes in steelmaking blast furnaces, the effect will be better than using it directly as a plugging material for molten iron holes. The sales price is about 1,000 yuan/t, and it has a relatively good prospect.

Chemical Industry

Production of Magnesium Carbonate

The production of magnesium carbonate requires the chemical composition of dolomite (%) as follows: MgO>18, CaO>29, SiO2<4, and there is no definite requirement for the content of K2O, Na2O and acid insoluble matter. At present, there are mainly three types of magnesium carbonate produced: light magnesium carbonate, light spherical magnesium carbonate and light transparent magnesium carbonate.

1、Production and application of light magnesium carbonate. In the industrial production of light magnesium carbonate, there are three main production methods due to different raw materials: dolomite carbonization method, brine carbonization method and ammonium sulfate conversion method. Due to the wide distribution of dolomite ore, large reserves, low cost, easy production control and good product quality, the dolomite carbonization method is currently widely used in China to produce light magnesium carbonate. This product is a basic raw material for inorganic chemicals, mainly used to manufacture magnesium salts, magnesium oxide, elemental magnesium, fireproof materials, printing inks, ceramics, daily chemicals, rubber products fillers and reinforcing agents, and can also be used in shipbuilding, boilers, steelmaking, glass, pigments, medicine and other industries.

2、Production and application of light spherical magnesium carbonate. Light spherical magnesium carbonate is also called spherical magnesium carbonate. It is mainly prepared with soluble magnesium salts and carbonates as raw materials. Due to the high price of raw materials, its production cost is relatively high. For this reason, dolomite can be used as raw material to produce spherical magnesium carbonate. It has good filling, dispersibility and fluidity, can improve the tensile strength and wear resistance of rubber, is an excellent filler and reinforcing agent for rubber, plastic and other products, and can also be used as a filler in paint, coating, toothpaste, cosmetics and pharmaceutical industries.

3、Production and application of light transparent magnesium carbonate. Light transparent magnesium carbonate is also called transparent magnesium carbonate. Its main characteristics are fine particles and uniform particle size. It belongs to fine inorganic chemical products. In addition to being used as an additive in paints, coatings, inks and toothpaste, pharmaceuticals, cosmetics, etc., it is mainly used as a filler and reinforcing agent for transparent or light-colored rubber products.

Production of magnesium oxide

As a filler, magnesium oxide is widely used in rubber, enamel, wire and cable industries. In addition, magnesium oxide is also an indispensable refractory material. At present, the new process for extracting magnesium oxide from dolomite in China is the dolomite circulation method.

In addition, the production process and method of preparing special silicon steel grade magnesium oxide with dolomite as the main raw material have also been developed.

Production of magnesium sulfate

Magnesium sulfate crystals (MgSO4·7H2O), also known as epsom salt, are used in medicine, agriculture, cement, printing and dyeing, food and other aspects. At present, the magnesium sulfate industry is developing rapidly in the world. MgSO4·7H2O is mainly produced by bitter extraction or seawater beach field sun drying. There are also reports of using dolomite as a raw material to prepare MgSO4·7H2O crystals by sulfuric acid method. Using dolomite to produce magnesium sulfate can not only obtain magnesium sulfate (MgSO4·7H2O) crystals, but also obtain by-product CaSO4·H2O.

Production of magnesium hydroxide

Magnesium hydroxide can be produced by the above intermediate process of producing magnesium oxide, or by decomposing dolomite by dolomite ammoniation or acid method.

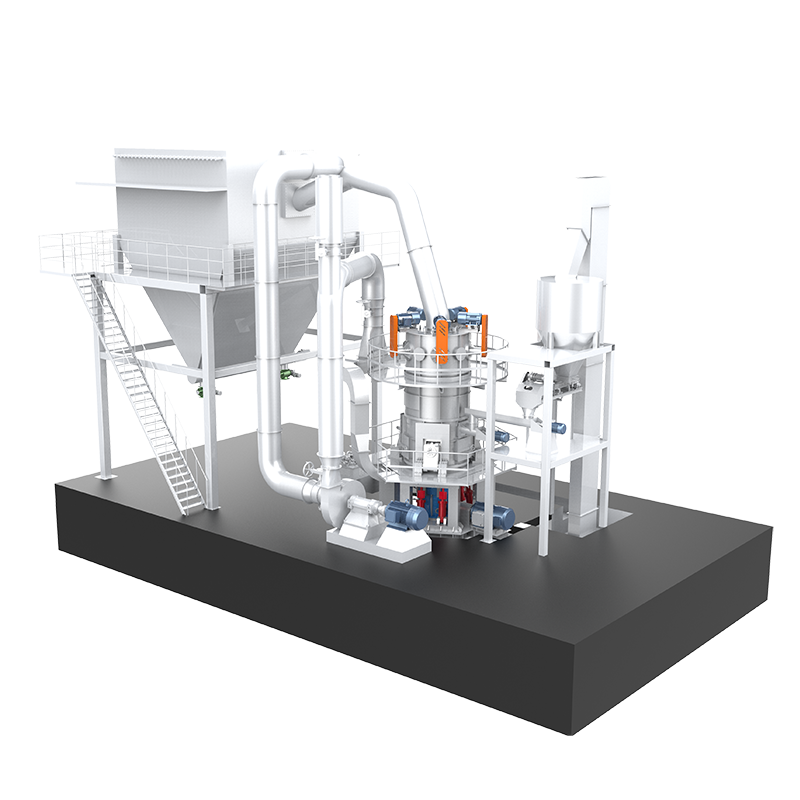

Production of dolomite powder

Dolomite becomes dolomite powder after being sorted, crushed and ground to 325-1250 mesh. When dolomite powder is added to natural rubber and synthetic rubber, its rubber properties are basically the same as those of light calcium powder, but the cost is lower than that of light calcium powder. Dolomite is used to produce universal calcium magnesium powder for rubber. As a new type of filler and colorant, it can partially or completely replace light calcium powder and lead powder.

Surface-modified dolomite powder can greatly increase the reinforcing properties of rubber products. Modified dolomite powder is to coat the surface of dolomite powder with a surface modifier and then use it as a filler. Commonly used surface modifiers include stearic acid or stearic acid, titanate, zirconium aluminum acid, mixed silane coupling agent, etc.

The purpose of modification is to change the alkalinity of dolomite powder surface, overcome the bonding performance between filler and rubber, reduce shrinkage and internal stress, prevent crack propagation, and improve the processing performance of product strength.

Production of nano calcium carbonate coated dolomite powder

Dolomite is coated with nano calcium carbonate, which is its surface modifier. It can blunt the sharp edges and corners formed by mechanical crushing of dolomite, and make the flat crystal cleavage surface rough. The plane with greater roughness can reduce the contact angle, and it will also be more easily infiltrated by the coupling agent, so it is more inclined to form a good interface bonding with the polymer matrix; for nano calcium carbonate, it is tightly coated on the surface of micron-sized particles, and the overall scale is micron-sized, so there is no dispersion problem, and the whole particle is a solid core, unlike agglomerates, there are no gaps, which reduces the occurrence of defects; nano coated particles have the advantages of calcium carbonate and can broaden the application field of other dark powders; because the surface coated calcium carbonate is nanometer-sized, the specific surface area of the coated particles is greatly increased, and the surface energy and chemical activity of the particles are improved, so that the inorganic filler particles and organic polymers can be better bonded to form a good interface.

Building materials industry

Development of magnesium cementitious materials

The main raw material of magnesium cementitious materials is MgO, which is produced from magnesite. People are now considering using dolomite to replace magnesite to produce MgO. Dolomite (CaMg[CO3]2) is a complex salt composed of CaCO3 and MgCO3. When calcined at about 790°C, it can decompose MgO, while CaCO3 does not decompose. The decomposed MgO is used as the raw material of the cementitious material, and CaCO3 is used as a filler that does not have a chemical effect, so that the harmful component CaO will not appear. Then the active MgO is mixed with the MgCl2 aqueous solution, stirred, molded and cured to produce high-strength magnesium oxychloride cement products.

Another important use of dolomite is to make magnesium oxychloride cement. This magnesium-containing cement has good compressive strength, flexural strength and corrosion resistance. In particular, the magnesium oxychloride cement prepared by caustic powder prepared by flame-muffle calcination of dolomite has better stability. Magnesium-containing cement has been widely used in floor blocks, fast-setting pavement paving, and repair of pavement cracks and fissures.

In addition, after calcining dolomite to generate caustic dolomite, it can also be processed into magnesium hydroxide cement and magnesium sulfate cement. These two non-hydraulic cementing materials have the advantages of simple production process, fast setting and hardening, high strength, strong bonding, good elasticity, wear resistance, convenient molding, low energy consumption, etc., and have high development and use value. It can be used to produce plaster mortar, concrete, wood-like magnesia products (sawn boards, particle boards, sound insulation boards, insulation boards) and artificial marble, etc., especially for bonding organic materials and filling damaged, cracked and peeled parts of cement products. Magnesium floor tiles have the elasticity, toughness and thermal insulation properties of wooden floors, and are fireproof and anti-insect, water-resistant, non-cracking, and cheap. It is made of magnesium-containing cement (made of magnesium chloride or magnesium sulfate solution mixed with caustic dolomite powder) as a binder, and then some fillers are added. Adding 10% to 20% additives (red shale, fly ash, talcum powder or dolomite powder) to magnesium-containing cement can overcome the disadvantages of magnesia floor tiles, such as easy warping and deformation, surface moisture absorption and brine return. The products are widely used in industrial plants, floors, walls and columns of public buildings and civil buildings.

In recent years, with the continuous development of the construction industry, the development and application of siliceous dolomite has been promoted. Dolomite has not only become the main mineral raw material for artificial marble and terrazzo, but also some dolomites with tight structure and fine texture have been rapidly developed as decorative materials and craft materials. It is reported that the magnesium composite material fired with high-quality dolomite as the main material is further processed into new decorative materials such as floor tiles, wall tiles and panels. It has many characteristics such as light weight, high strength, anti-aging, beautiful appearance, etc., and is deeply favored by people. Decorative railings and decorations made of dolomite as the main material are also very popular.

Application in glass production

Glass production

Dolomite and limestone are the third largest components of glass raw materials besides silica sand and soda ash. In the production of bottle glass, soda ash is the most expensive component. Adding limestone can partially replace soda ash, but it will have adverse effects. The method of introducing magnesium oxide in dolomite can further reduce costs. Dolomite can also provide calcium oxide in the glass industry, and add soda ash-ash-siliceous system to play a role as a flux. In addition, dolomite can reduce glass aging, prevent chemical erosion caused by the atmosphere or moisture, improve the plasticity of colored glass, and increase glass strength.

Adding a certain amount of dolomite powder to glass manufacturing can effectively reduce the high-temperature viscosity of glass and improve the chemical stability and mechanical strength of the product. Practice has also shown that the introduction of dolomite powder in the preparation of low-temperature ceramics and float glass ingredients can significantly save energy consumption and obtain good social and economic benefits. The quality requirements of dolomite for glass and ceramics are generally: MgO ≥ 19%, CaO ≥ 26%, Al2O3 < 1%, Fe2O3 < 0.2%.

Production of microcrystalline glass

Gold mine tailings, dolomite, etc. are used as raw materials, and Cr2O3 is used as a nucleating agent to make microcrystalline glass and cast stone plate products. Their performance indicators are better than natural marble and granite. They are suitable for building materials, chemical corrosion-resistant materials or wear-resistant materials for metallurgy and mining industries, opening up an effective way to solve environmental pollution problems.

Application in ceramic production

Dolomite is used in blanks and glazes, and MgO and CaCO3 are introduced to replace talc and calcite. The role of MgO is to: change the composition of the mixing system, thereby reducing the firing temperature of the blank; promote the dissolution of quartz and the formation of mullite, increase the amount of quartz, and reduce the amount of feldspar, thereby increasing the transparency of the blank. The addition of dolomite to the glaze is less likely to smoke than the addition of calcite, and crystallization rarely occurs. This is because dolomite is a complex salt mineral.

The dolomite limestone mixture made of dolomite and marl can be used to make calcium feldspar and diopside-wollastonite clinker, which is suitable for fast-firing porcelain. When making wall tiles and fine pottery, the cost of this clinker is lower than that of calcium-magnesium compounds synthesized separately.

Other industries

Application in agriculture

Used to neutralize the acidity in the soil. Since the long-term use of fertilizers such as urea can easily make the soil acidic, dolomite can be directly added to urea to keep the soil at an appropriate pH value, which can generally increase crop yields by 15% to 40%, and can also improve the efficacy of herbicides. The herbicide effect is best when the pH is 6.0 to 6.2. Dolomite can also compensate for the loss of magnesium content in the soil. Dolomite particles of 1.2 to 0.8um can flow freely. Used as a filler for fertilizers, it can improve the conditions for plants to use soil nutrients, reduce agglomeration, and facilitate the adjustment of fertilizer ratios.

With the development of the magnesium smelting industry, more and more tailings have occupied arable land, increasing the environmental load. How to comprehensively utilize this part of the resources has now found a better way out, that is, using the tailings after smelting metal magnesium with dolomite to produce magnesium-potassium multi-compound fertilizers. In addition, it is reported that dolomite can also be used instead of serpentine to produce calcium-magnesium-phosphate fertilizers.

Application in environmental protection

Dolomite fine powder can be used to improve the flying of dust in coal mines, prevent and delay coal dust explosions. Dolomite powder is used as a filter material for water treatment, especially for neutralization from drinking water to industrial water, swimming pool water, etc., as well as for the removal of iron, manganese, silicates, etc. Research in this area is in-depth.

Application in livestock and poultry feed

Calcium and magnesium are both essential nutrients for animals. Adding an appropriate amount of dolomite powder (or 0.1-1.5mm particles) to livestock and poultry feed is very beneficial for promoting animal growth and development and reducing diseases. It is worth noting that when developing and utilizing dolomite for feeding, the content of harmful elements must be strictly controlled. The specific requirements are as follows: Pb≤30PPM, AS≤10PPM; Hg≤0.1PPM, F≤2000PPM, acid insoluble matter≤5%, -2mm magnetic metal particles≯0.8%.

Disinfectant for livestock and poultry

Dolomite, which has a wide range of uses, has been studied by a research team from the Department of Agriculture at Tottori University in Japan, and a new material with a significant preventive effect on influenza viruses has been developed.

The dolomite used in this study was provided by Uase Electric Co., Ltd. The researchers found that when the new material they developed was put together with the avian influenza virus to make a 0.6% concentration solution and shaken for 10 minutes, the number of viruses would be reduced to less than 1/100,000 of the original. This new material also has a significant killing effect on other viruses. Masks made of this new material can also resist foreign viruses.

Paint

After the commonly used water selection, drying, crushing, grinding, grading and other processes, and then chemical treatment, surface treatment, pH value adjustment, rinsing and other processes, a new type of body pigment is obtained. Its chemical composition is stable, and it has many advantages such as weather resistance, anti-settling, fine powder, easy dispersion, high whiteness, low cost, and unique process, and can be used for various paints. The coating produced has the characteristics of being able to reduce the amount of titanium dioxide used, high hardness, good hand feel, good fluidity, strong adhesion, etc., and its application effect is better than that of heavy calcium carbonate.

Dolomite is a non-metallic mineral resource that can be developed and utilized in many ways. With the development of modern science and technology, the development and application of dolomite has penetrated into various fields of social development and has become a mineral resource with great economic value.