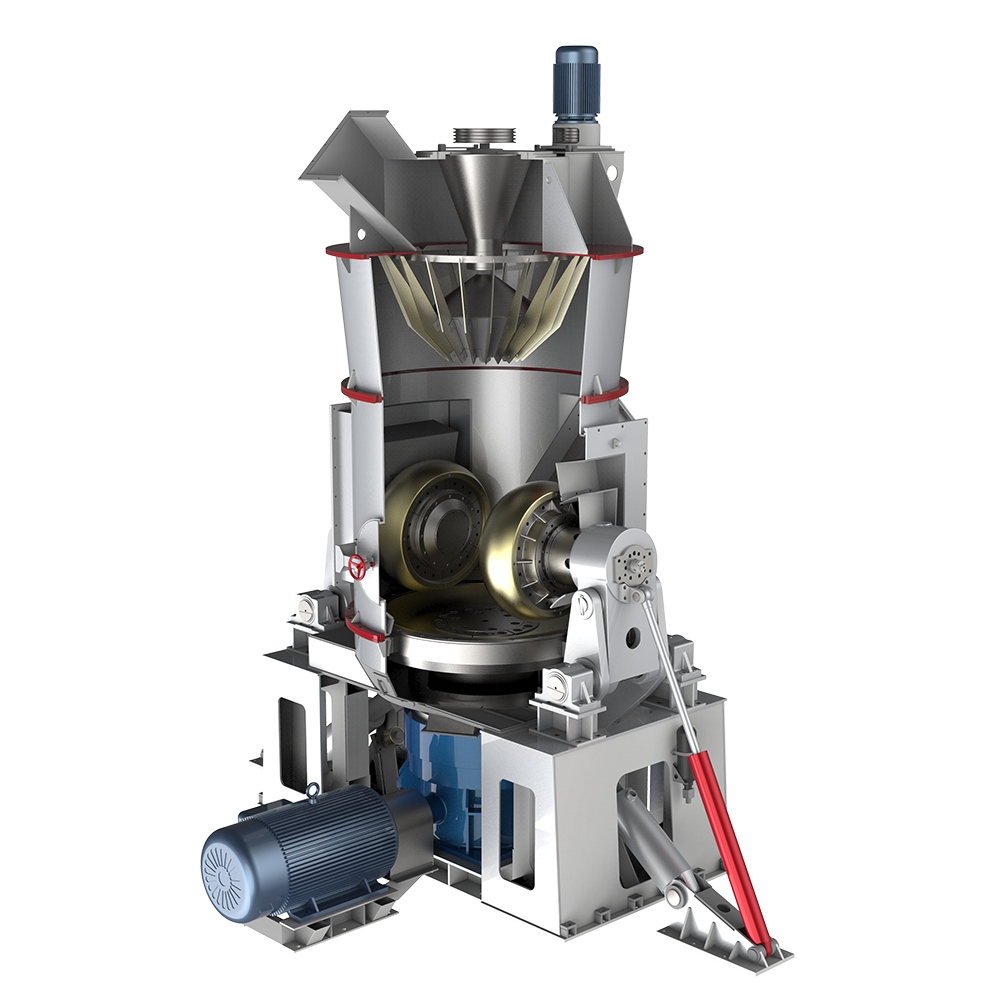

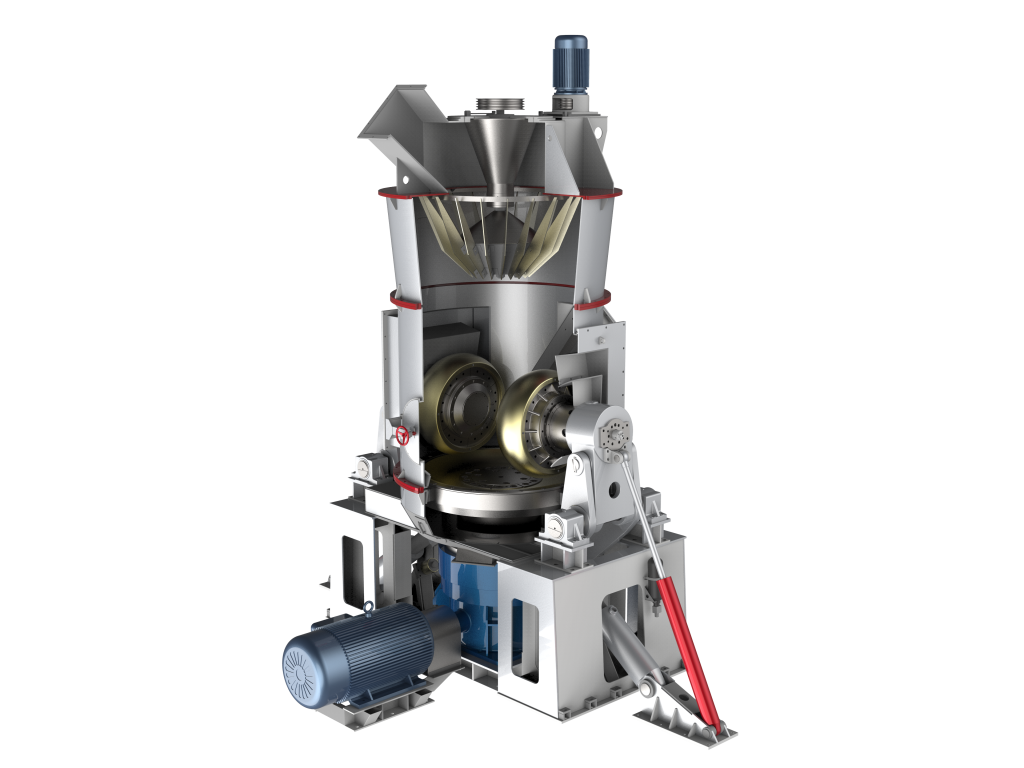

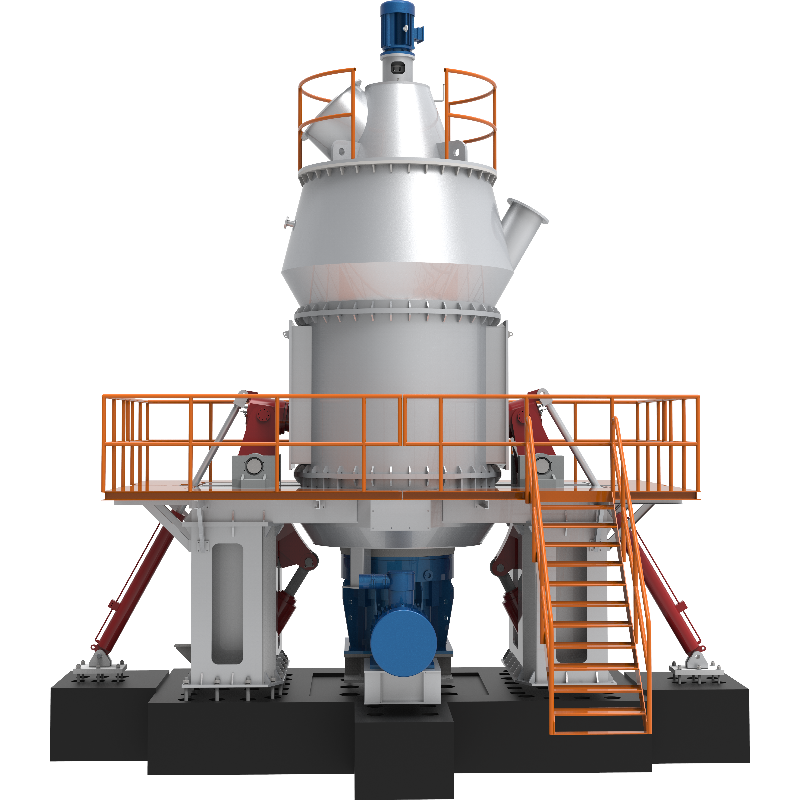

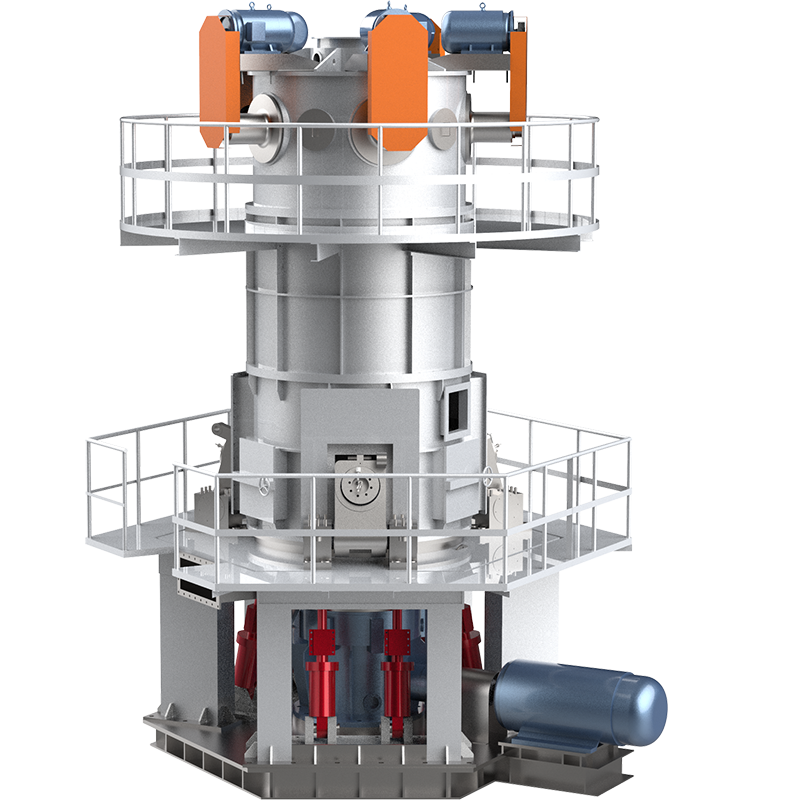

CRLM1300 Vertical Mill-Vertical Roller Mill

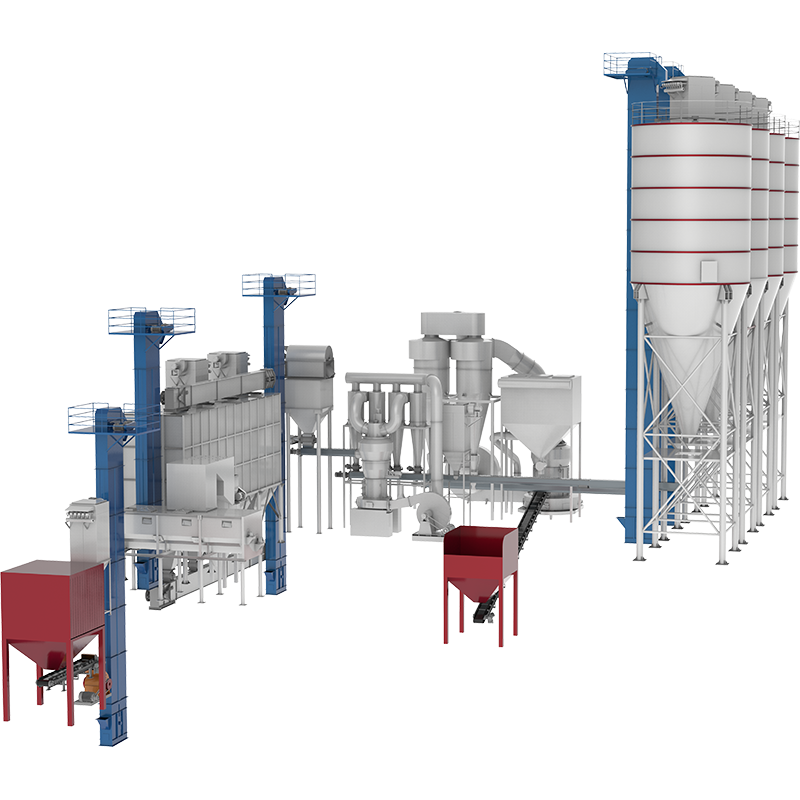

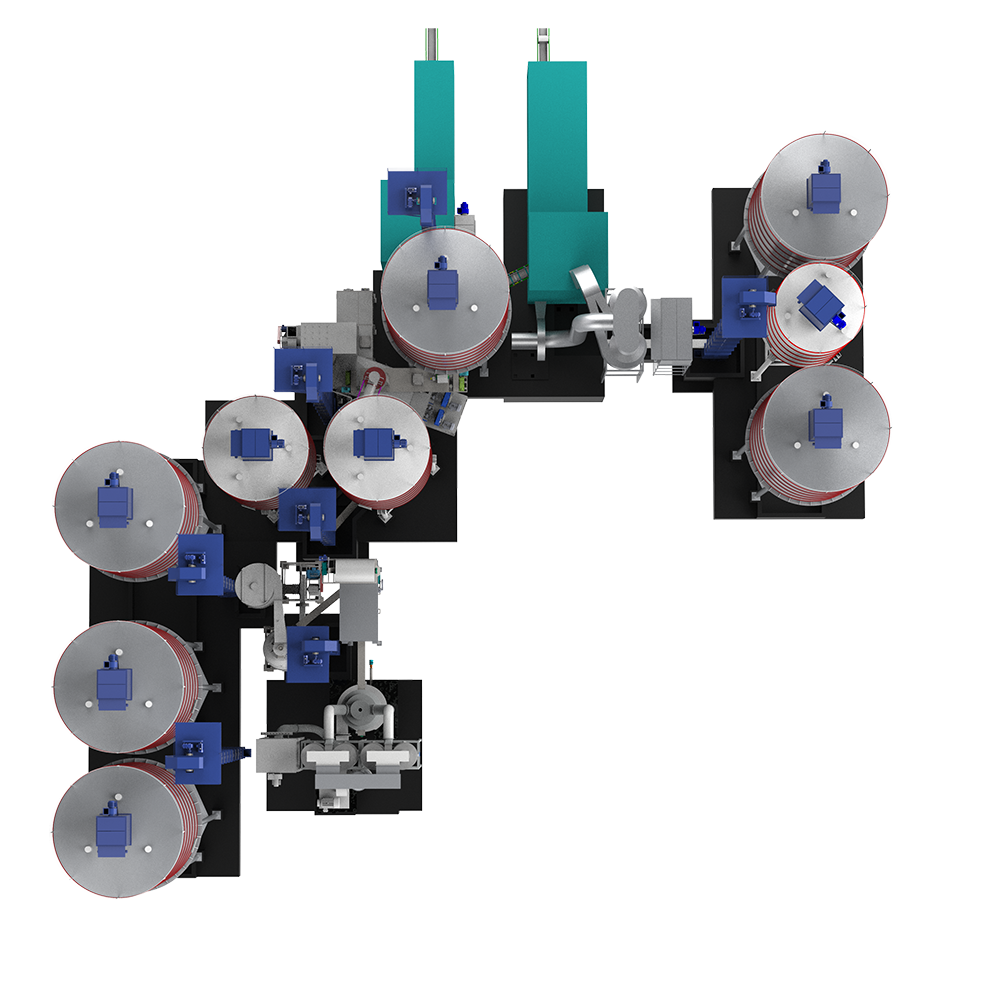

Shcronus has launched the CRLM1300 vertical mill which integrates drying and grinding with high efficiency and energy saving. CRLM1300 vertical mil can be widely used in cement, metallurgy chemical industry, non-metallic ore, non-ferrous metals ore powder grinding, and electric power. Compared with the CRLM1300 vertical mill and ball mill system, the land area can be […]