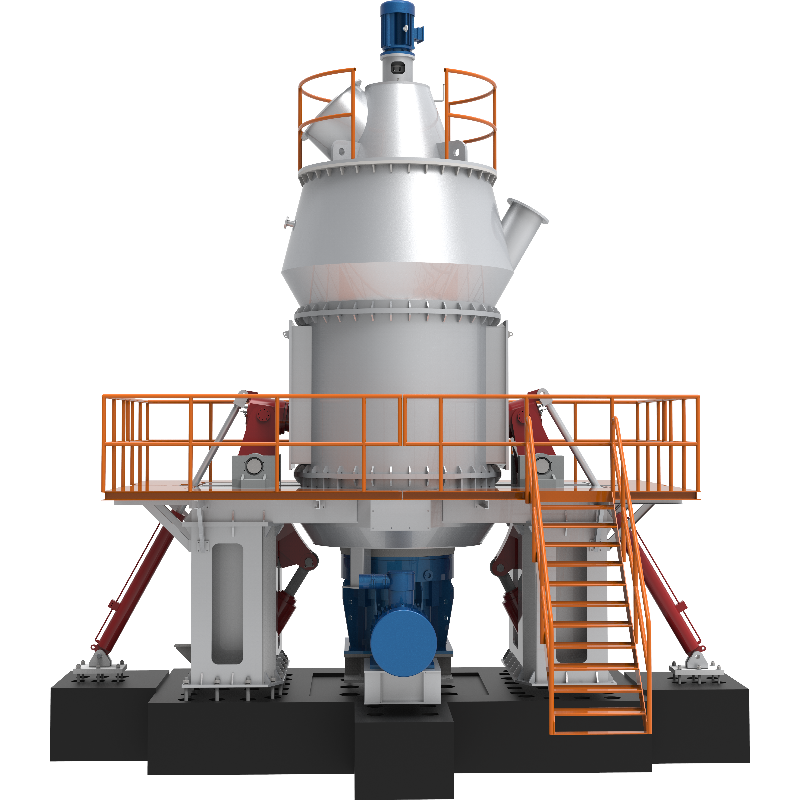

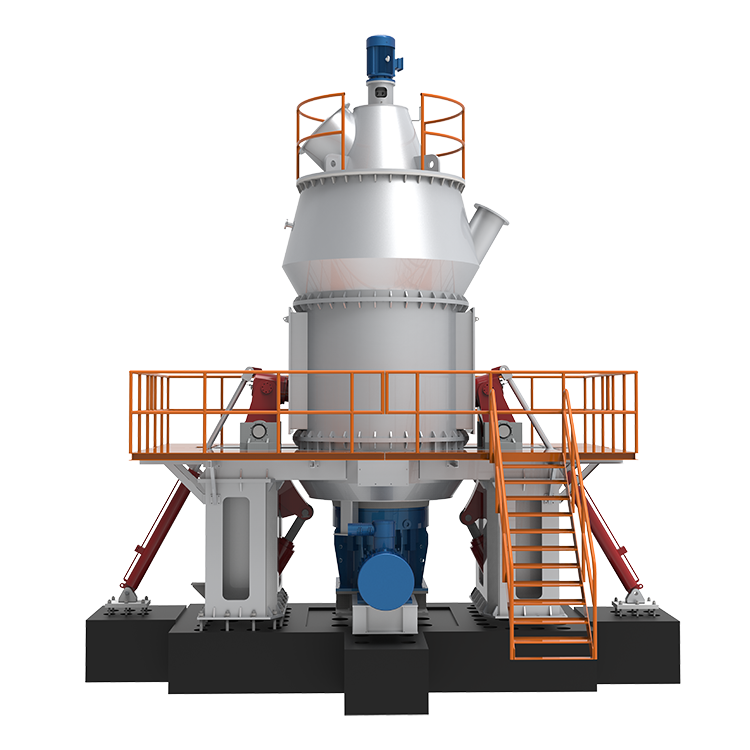

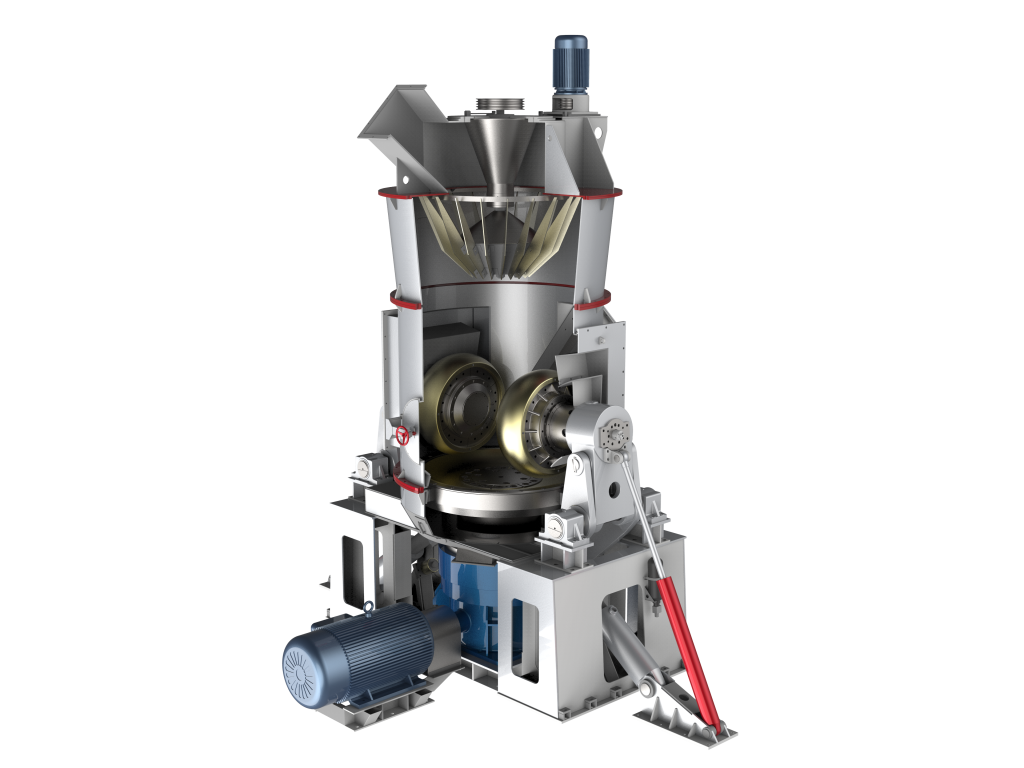

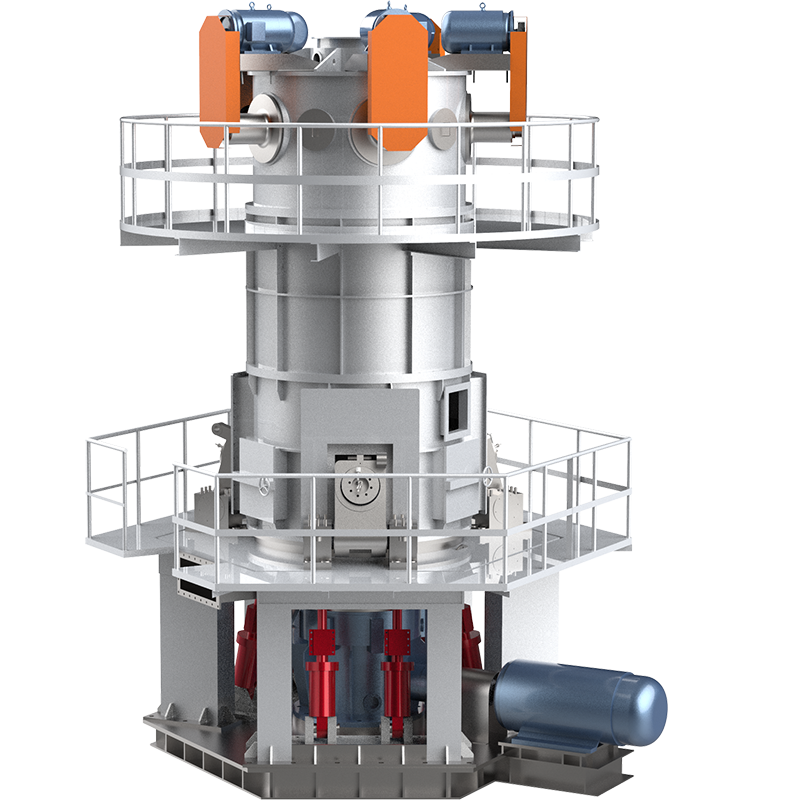

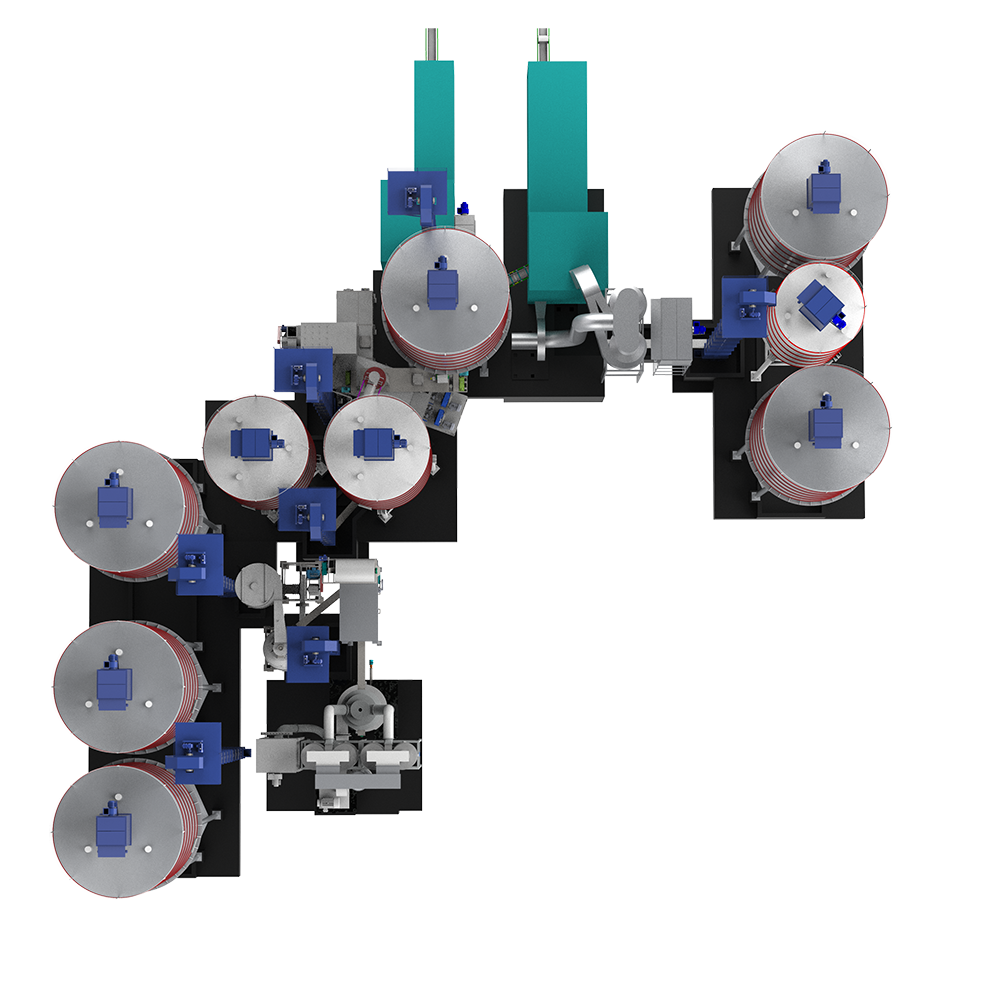

CRRM Series Vertical Grinding Mill

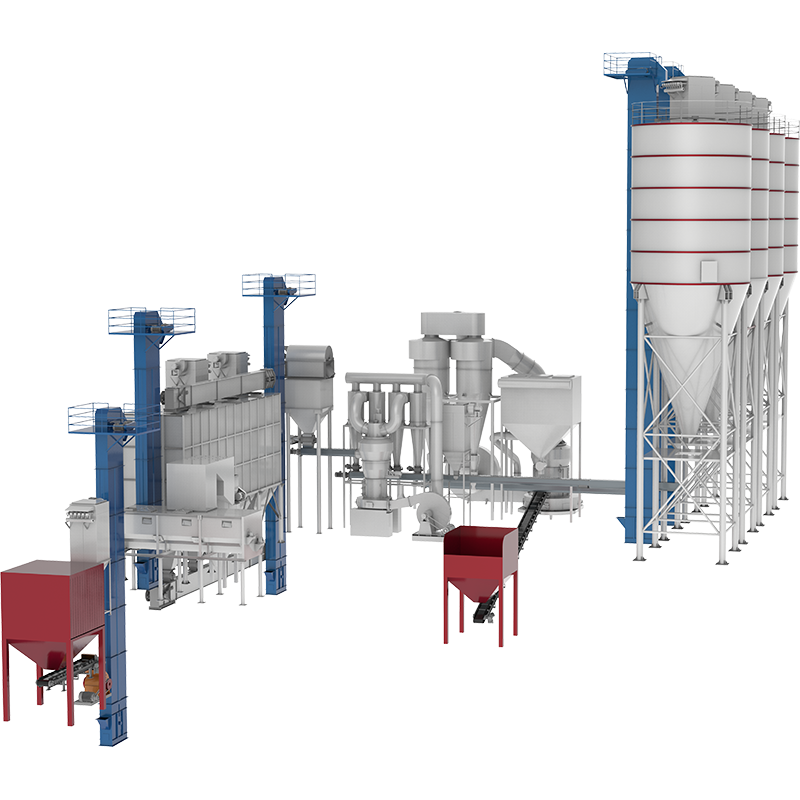

1. Introduction The CRRM series vertical grinding mill is a highly efficient and energy-saving grinding equipment widely used in industries such as mining, metallurgy, chemical engineering, and building materials. It is primarily used for grinding non-flammable and non-explosive brittle materials, such as limestone, calcite, marble, and barite. With its high efficiency, energy-saving features, and environmental […]