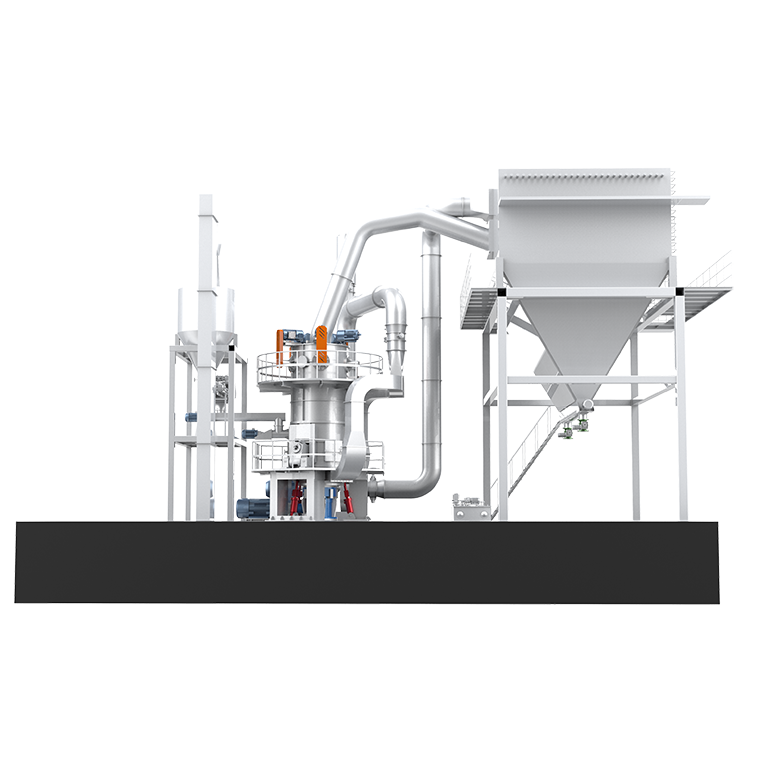

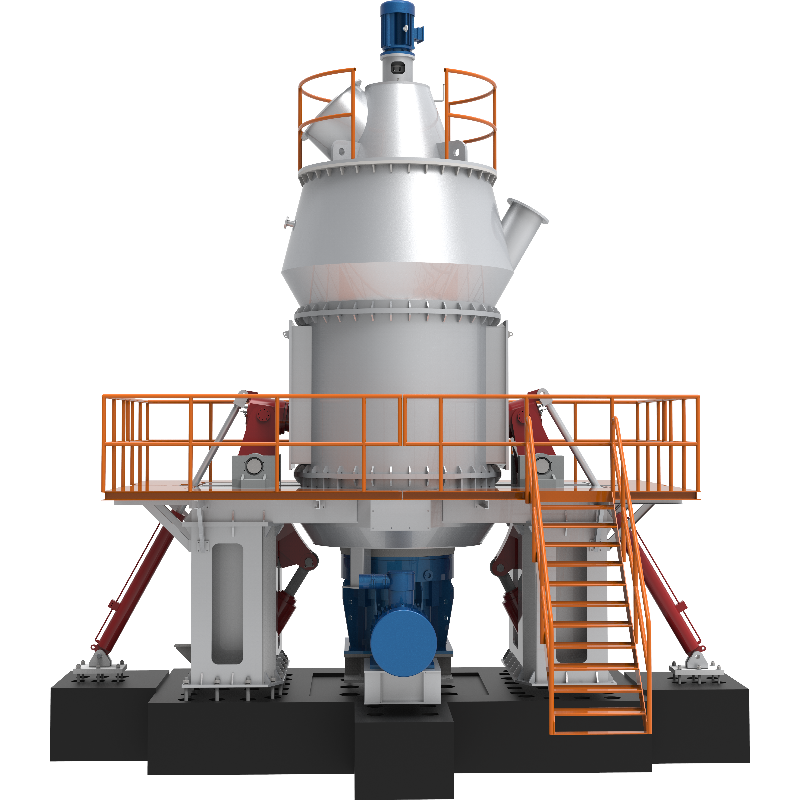

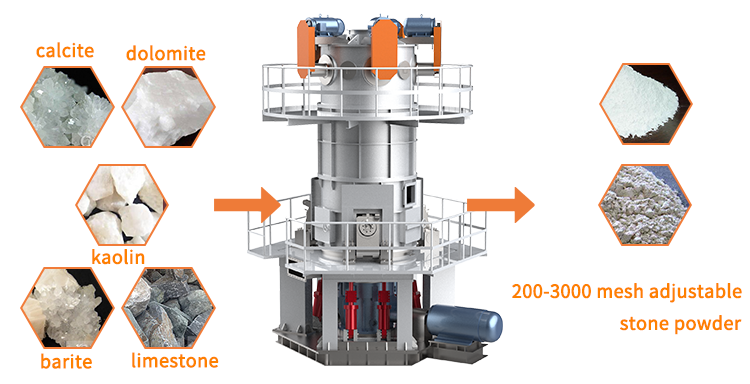

Vertical grinding mill plays an important role in cement production and is one of the key equipment in the cement production process. It is mainly used to grind cement raw materials into fine powder, thereby improving the production efficiency and product quality of cement production lines.

Structure, Function of Cement Vertical Grinding Mill

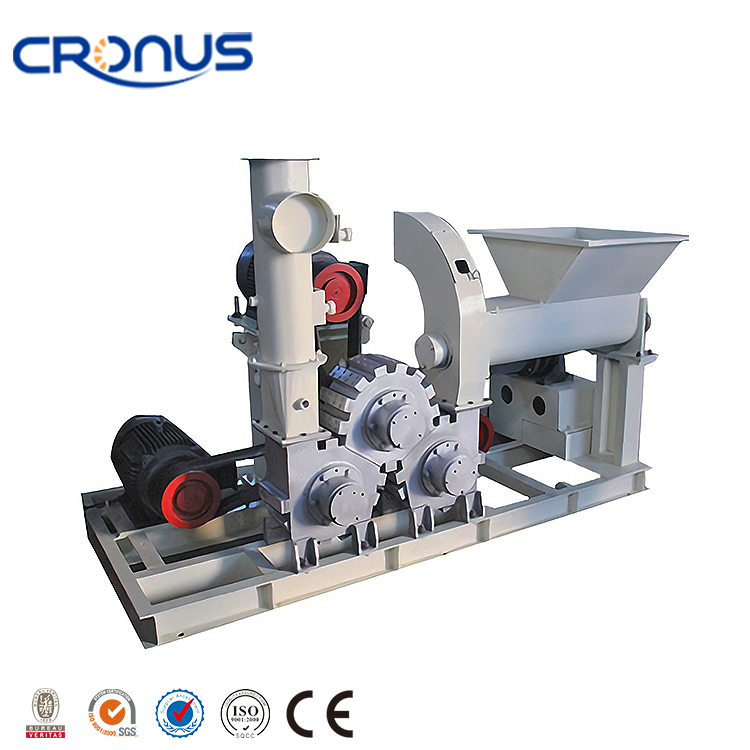

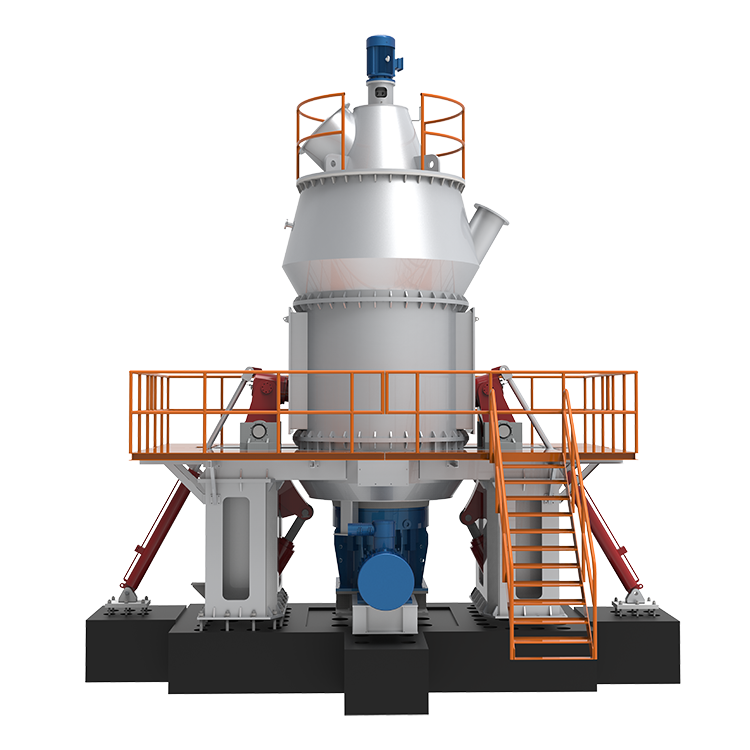

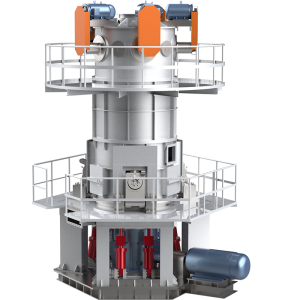

Cement Vertical Grinding Mill is generally composed of grinding disc, grinding roller, lubrication device, inlet and outlet, etc. The grinding disc is the main part of the equipment, which consists of a disc-shaped platform and a grinding surface on it. The grinding surface is made of hard materials such as grinding wheels and is used to grind cement raw materials. The grinding roller is located above the grinding disc and is used to apply pressure to grind the raw materials. The lubrication device is used to provide lubrication and cooling to the grinding roller and grinding disc to prevent the equipment from overheating or overloading.

At the same time, the cement Vertical Grinding Mill also needs regular maintenance and maintenance to ensure the normal operation and production efficiency of the equipment. Once the vibration amplitude of the cement Vertical Grinding Mill is too large, it may cause problems such as high equipment noise, equipment damage or shutdown, which need to be solved in time.

The reason why the vertical mill vibrates

- Defects or failures in the equipment itself, such as bearing damage, gear wear, etc., which cause the machine to be unbalanced or unstable.

- Uneven raw material feeding or excessive moisture content of the material causes uneven gaps between the grinding roller and the grinding disc, causing vibration.

- Wear or damage to the surface of the grinding roller causes the grinding roller to be unbalanced or the gaps between the grinding roller and the grinding disc to be uneven.

- The grinding disc is disturbed or contaminated by foreign matter, causing imbalance or instability.

- Improper operation or untimely maintenance, such as improper operation causing unstable operation of the equipment, or failure to clean up dust and debris inside the equipment in time.

How to deal with large vibration of vertical mill

- Check whether the equipment has faults or defects: such as bearing damage, gear wear, etc., which may cause the machine to be unbalanced or unstable and need to be repaired or replaced.

- Adjust the raw material feeding method: Check the feeding of raw materials to ensure that the raw materials are fed evenly and try to avoid excessive moisture content of the materials.

- Replace the grinding roller or grinding disc: Check whether the surface of the grinding roller is worn or damaged. If the grinding roller is unbalanced or the gap between the grinding roller and the grinding disc is uneven, you can consider replacing the grinding roller or grinding disc.

- Clean up the dust and debris inside the equipment: Clean up the dust and debris inside the equipment in time to ensure the normal operation of the equipment.

- Strengthen maintenance: Operate and maintain according to the requirements of the equipment manual, check the operation of the equipment regularly, and solve problems in time.

For different reasons, it is necessary to choose corresponding solutions according to the actual situation, comprehensively consider the equipment itself, raw material quality, operating environment and other factors, so as to achieve the purpose of solving the vibration problem of cement Vertical grinding mill.

In daily work, in order to ensure the normal operation of the equipment, it is necessary to regularly check the operation of the equipment, find problems in time and solve them. At the same time, it is necessary to operate and maintain according to the requirements of the equipment manual to ensure that the equipment operates in a safe and stable state.