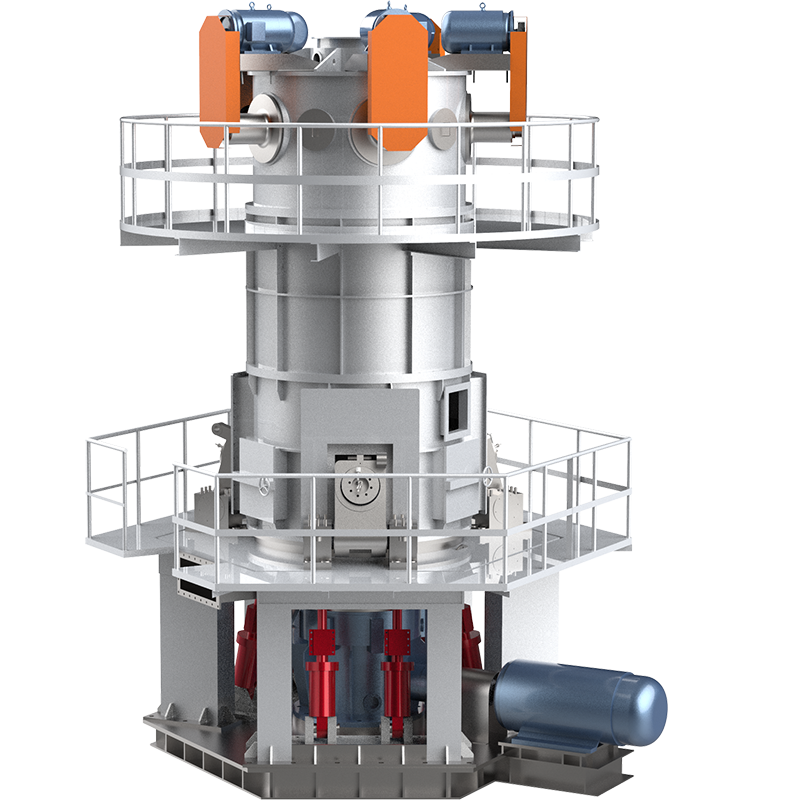

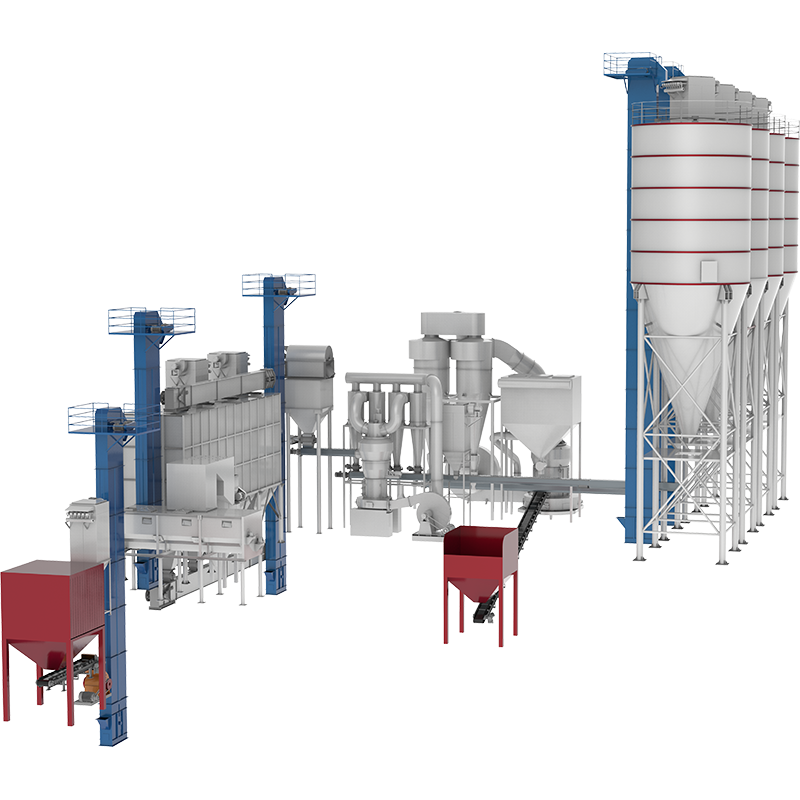

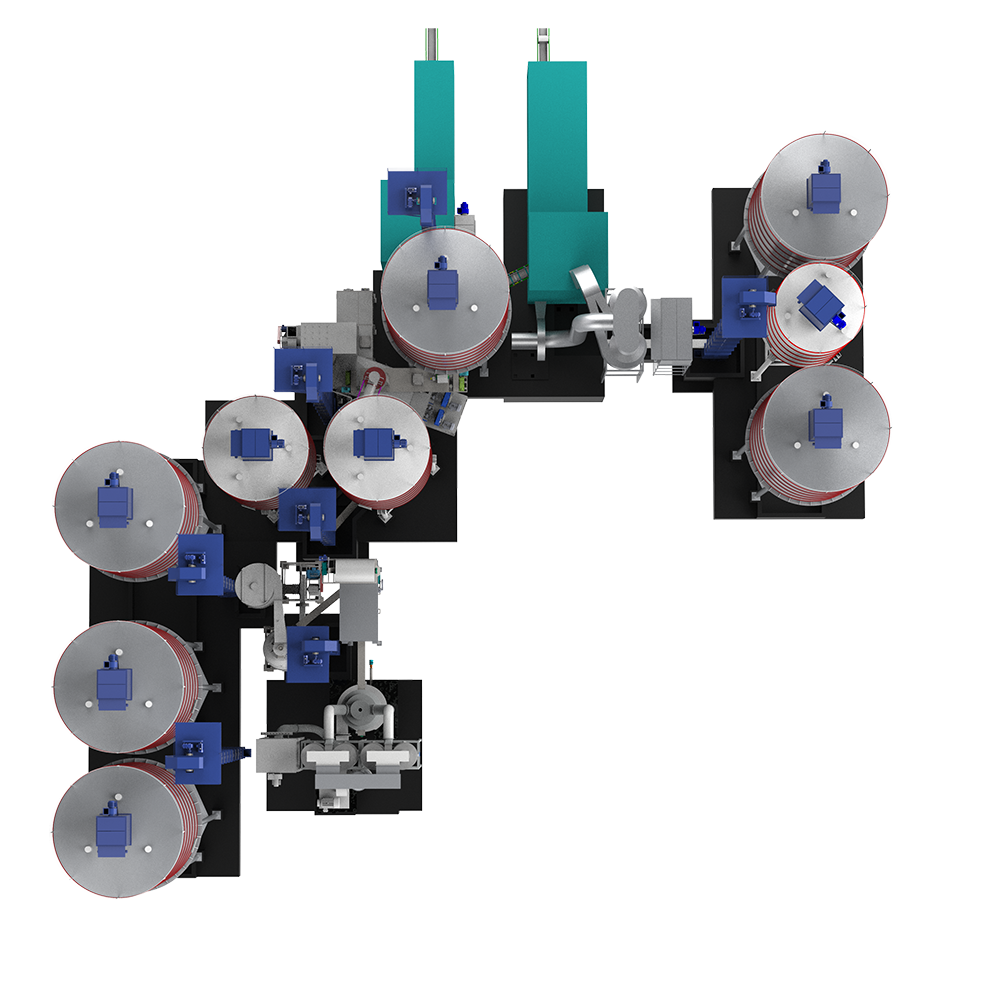

Carbon black grinding usually uses Ultrafine vertical mill, which is suitable for ultra-fine powder processing of conventional carbon black and carbon black materials. This equipment can process materials with humidity less than 8% and Mohs hardness below 6, with large feed particle size and average discharge particle size up to 0.010mm. Carbon black grinding production line is widely used in dyes, rubber reinforcing agents, inks, paints and other industries. It is an important equipment for carbon black processing. The ground carbon black can be used for dyes and rubber reinforcing agents, and has a high utilization value.

Ultrafine vertical mill performance characteristics

- Safe and stable operation: The Ultrafine vertical mil has a simple structural combination and compact design. The equipment is a three-dimensional structure with strong completeness. The equipment is very stable during operation, and there will be no material blockage or shutdown. The safety performance of the equipment is very good.

- High grinding output: The grinding process of the mill has been reasonably optimized, and the grinding roller device of the equipment has been reasonably improved. The grinding efficiency has been greatly improved, and the screening rate has reached 99%.

- Good grinding effect: The quality of the finished material ground by the mill is also very good. The quality of the carbon black finished material is good, the fineness is uniform, and it does not contain impurities. The industrial utilization value is very high.

- Long service life: The durability of the mill is also very strong. The body and components of the equipment at all levels are made of new materials. The wear rate and failure rate of the equipment are low, and the service life is extended.

- Significant environmental protection effect: The body of the mill has strong sealing, and the equipment is produced by negative pressure operation. The material grinding process produces less dust and low noise, which can effectively improve its working environment.

Why choose our Cronus ultrafine grinding machine?

Advanced technical design

Equipped with advanced automatic control system, one-button operation and remote monitoring are realized, manual intervention is reduced, and production efficiency is improved.

Adopts high-efficiency energy-saving motor and optimized grinding structure, low energy consumption, and meets the requirements of green production.

Stable and reliable performance

The core components (such as grinding rollers and grinding rings) are made of high-strength wear-resistant materials to extend the service life of the equipment and reduce maintenance costs.

The equipment has a reasonable structural design, low vibration and low noise, ensuring long-term stable operation.

Wide range of applications

Equipment parameters can be adjusted according to the characteristics of different materials (such as hardness, humidity) to meet diversified production needs.

Cronus ultrafine grinding mill is suitable for ultrafine grinding of various materials such as carbon black, calcium carbonate, talcum powder, kaolin, etc., and is widely used in chemical, building materials, metallurgy, environmental protection and other fields.

User-friendly operation experience

Modular design facilitates disassembly and replacement of wearing parts, reducing downtime.

Even ordinary operators can quickly get started, reducing training costs.