Calcium hydroxide, with the chemical formula of Ca (OH)₂, is also called slaked lime or hydrated lime. It has extremely wide and indispensable applications in many fields such as environmental protection, chemical industry, construction, water treatment, etc. It is a vital inorganic compound. For related companies, whether they can have an efficient, stable and reliable calcium hydroxide production line is directly related to the production efficiency and economic benefits of the company. So, in a mixed market, how can we discern the pearls and select a high-quality calcium hydroxide production line supplier?

Key considerations for choosing a calcium hydroxide production line supplier

Reliability and market reputation

A high-quality supplier must have accumulated a good reputation in the industry and has a series of long-term, stable and successful customer cooperation cases. During the screening process, in-depth evaluation can be conducted from the following dimensions.

Customer feedback survey

Widely collect the real evaluation of the supplier's past cooperative customers, focusing on the stability of the equipment during actual operation, as well as the supplier's response speed, problem-solving ability and service quality in after-sales service.

Industry certification verification

Carefully check whether the supplier holds authoritative qualifications such as ISO quality management system certification, which is a strong proof of its standardized and standardized production management; at the same time, environmental compliance certification is also a key that cannot be ignored, ensuring that its production process meets the country's increasingly stringent environmental protection requirements.

Verification of the comprehensive strength of the enterprise

Fully verify the scale and technical strength of the supplier's R&D team, understand the scale of its production site, the advanced level of its production equipment, and its years of deep cultivation and rich experience in the field of calcium hydroxide production lines.

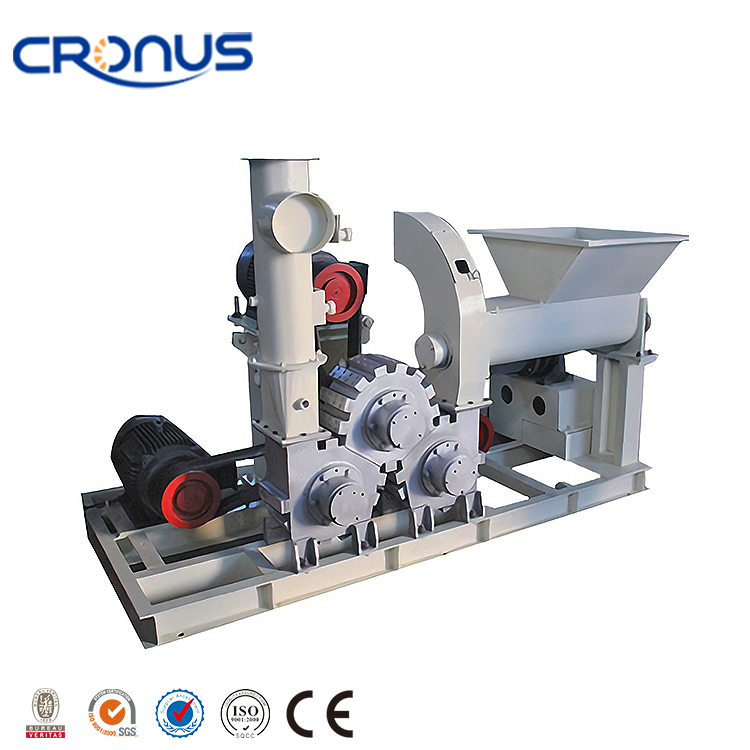

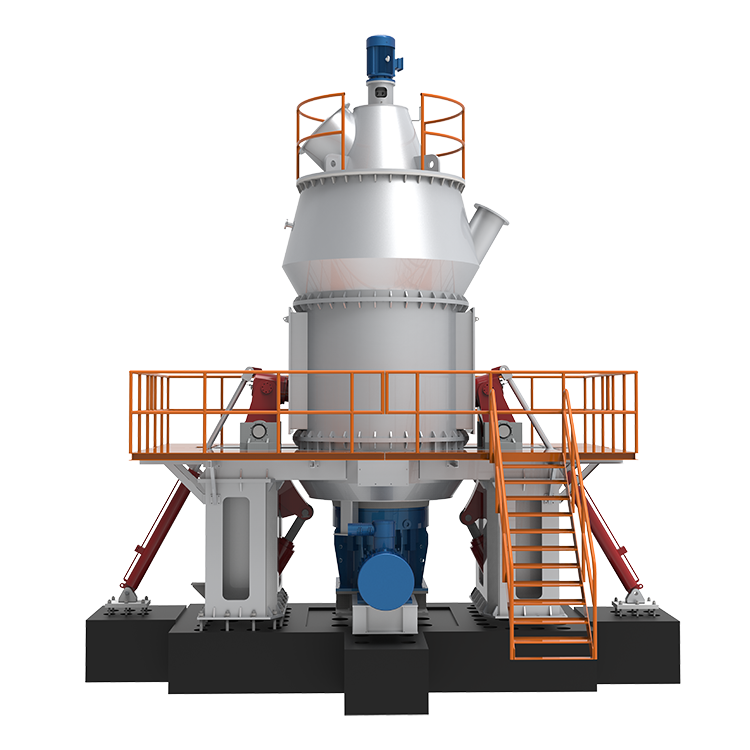

Take Cronus as an example. Its carefully built CRQ calcium hydroxide production line is a mature and reliable production solution launched by Cronus after repeated technical optimization and practical testing based on its deep accumulation of years of experience in the industry and cooperation with many important customers in the industry.

At present, the equipment of this production line has been successfully introduced into many important industries such as metallurgy, environmental protection, and chemical industry, and has gained extremely high market recognition and received high praise from many customers.

echnical background and innovative vitality

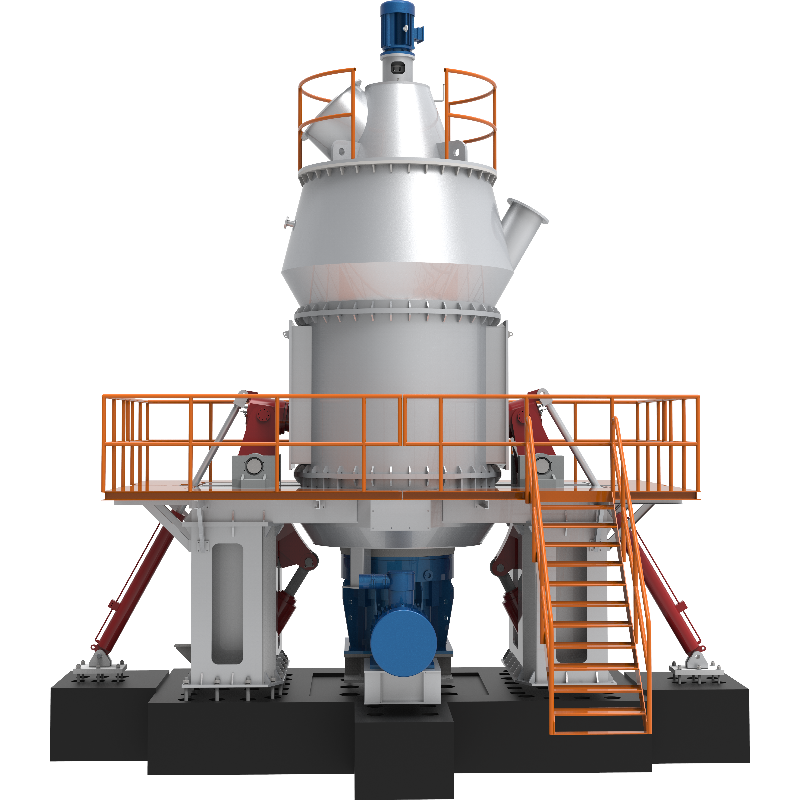

The production process of calcium hydroxide covers multiple complex and critical links such as digestion, grinding, and grading, which requires suppliers to have advanced process technology and strong equipment R&D and innovation capabilities.

Core equipment performance evaluation

focus on whether the digestion efficiency of the equipment is efficient, whether the fineness after grinding can be accurately controlled, and whether it has outstanding advantages in energy consumption control, which are key indicators that directly affect production quality and cost.

Intelligent degree evaluation

understand whether the production line provided by the supplier is equipped with an advanced automatic control system, whether the system can minimize manual intervention, thereby significantly improving the stability of the production process and the consistency of product quality.

Environmental protection technology compliance

confirm whether the technical means adopted by the supplier in key environmental protection links such as dust collection and wastewater treatment can fully meet or even exceed the current national environmental protection standards.

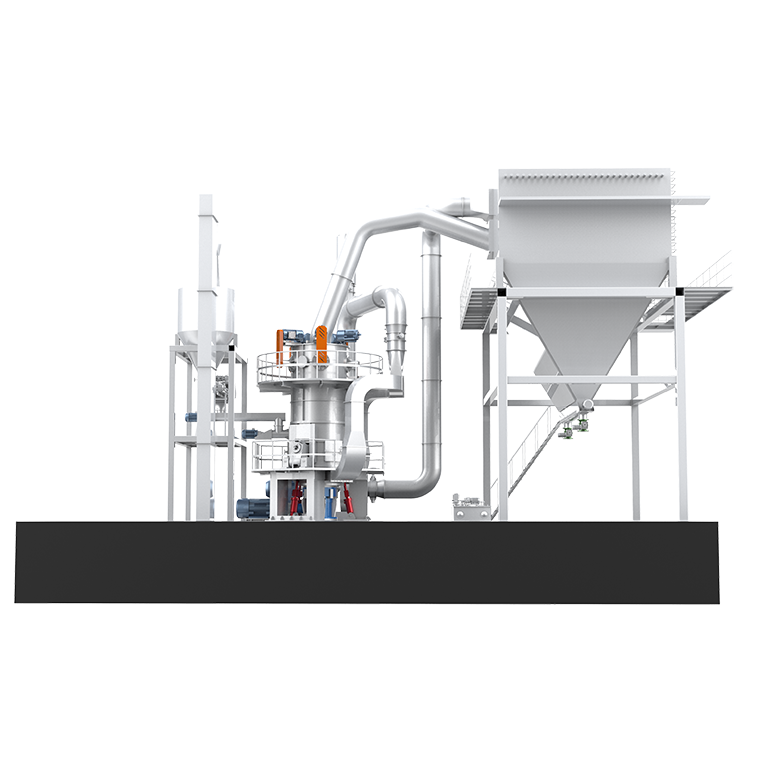

Excellent technical advantages demonstrated by the CRQ production line

The innovative use of the dual digestion process of "dynamic digestion (CRSH digester) + static digestion (delayed digestion bin)", this unique design greatly improves the conversion rate of lime and lays a solid foundation for subsequent production links.

The careful combination of "CRHG special grinding mill + CRXF powder selector" can not only ensure that the fineness of the finished product can be accurately adjusted between 80-600 mesh to meet the diverse needs of different industries, but also has significant results in reducing energy consumption, which can be reduced by more than 20% compared with similar equipment.

The production line adopts a fully enclosed design concept and performs well in dust emission control, with dust emissions below 10mg/m³, which fully meets the current stringent environmental protection requirements.

Customized service capabilities

Since different industries have their own unique requirements for the fineness, purity and production capacity of calcium hydroxide, it is particularly important for suppliers to provide personalized solutions.

Process adaptation: Suppliers need to reasonably adjust the configuration of the production line according to the characteristics of the raw materials used by customers, such as the activity of lime and the amount of impurities. Only in this way can we ensure that the production line can achieve the best production effect when processing different raw materials.

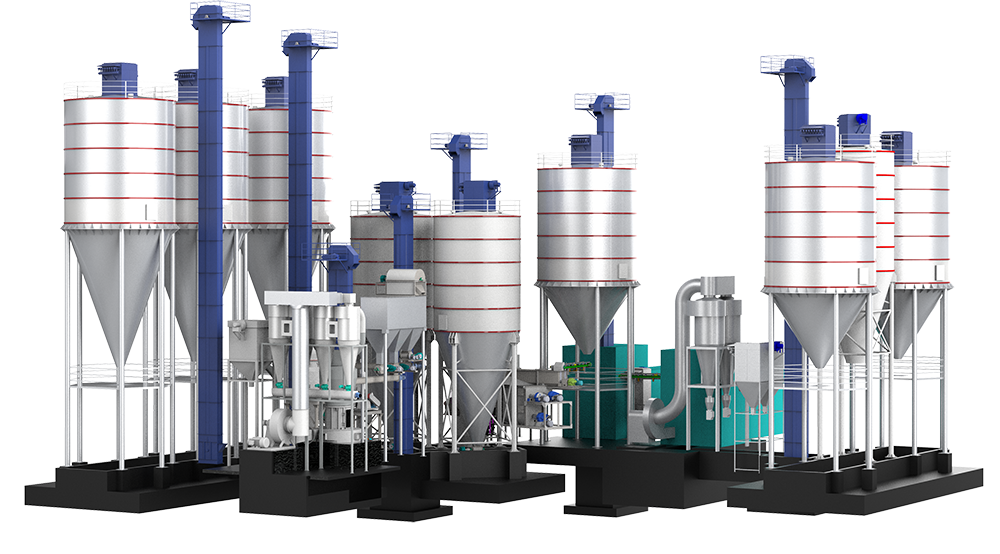

Capacity matching: It can support production capacity requirements of different scales from 5 to 30t/h, and has the ability to expand flexibly. Whether it is small-scale production of small enterprises or large-scale production capacity requirements of large enterprises, it can provide suitable solutions to meet the production needs of enterprises at different stages of development.

Special needs: For some special industries, such as the production of food-grade and pharmaceutical-grade calcium hydroxide, there are extremely strict requirements on the purity and heavy metal content of the product. High-quality suppliers should have the ability to create exclusive production lines for these special needs to ensure that the products meet the corresponding high standards.

Cronus has developed a series of customized solutions for the CRQ production line in response to different customer needs:

Calcium hydroxide for power plant desulfurization: Considering the high requirements for the reactivity of calcium hydroxide in the desulfurization process of power plants, cronus optimizes the CRQ production line so that the calcium hydroxide it produces has higher reactivity and can react more efficiently with sulfur in the flue gas, thereby significantly improving the desulfurization efficiency and helping power plants better meet environmental emission standards.

Calcium hydroxide for food additives: The food industry has extremely high requirements for product safety and purity. When cronus customizes the CRQ production line for calcium hydroxide for food additives, it strictly controls each link in the production process to ensure that indicators such as the heavy metal content of the product guarantee the quality and safety of food additives.

How to make the best choice?

In summary, choosing a high-quality calcium hydroxide production line supplier requires comprehensive evaluation from multiple dimensions:

Comprehensive evaluation of suppliers: comprehensively examine the technical strength of suppliers, including their performance in core equipment performance, intelligence level, environmental protection technology, etc.; understand their market reputation, and judge their reliability through customer evaluation, industry certification, etc.; evaluate customization capabilities to see whether they can meet the personalized production needs of enterprises; analyze cost-effectiveness, and weigh factors such as initial investment, operating costs and long-term benefits.

Reference to successful cases: learn from mature successful cases in the industry, such as the wide application and good performance of Kronos CRQ production line in multiple industries. By understanding these actual cases, enterprises can more intuitively recognize the advantages and applicability of products from different suppliers, and provide a strong reference for their own decision-making.

Field investigation: If conditions permit, enterprises should visit the supplier's equipment production line on site, observe the actual operation effect of the equipment, understand each link in the production process, communicate with the supplier's technical personnel and production personnel, and obtain first-hand information, so as to more accurately judge whether the supplier meets their own needs.

Choosing a supplier with advanced technology and reliable services is of vital importance to ensure the stable operation of the calcium hydroxide production line and bring long-term economic benefits to the company. With its innovative process, excellent performance and perfect customized services, the Cronus CRQ calcium hydroxide production line is undoubtedly a high-quality option that many companies should consider when choosing a calcium hydroxide production line supplier.

If you are interested in customized calcium hydroxide production line solutions, or have any technical consultation needs, please feel free to contact the professional team of Cronus. They will serve you wholeheartedly and help your company achieve greater success in the field of calcium hydroxide production.