Calcium hydroxide, a crucial inorganic chemical product, is widely used in construction, agriculture, environmental protection, and other industries. In its production process, the powder selection system is a core component, significantly influencing the particle size distribution, specific surface area, and final application performance of the product.

Overview of the Powder Selection System in Calcium Hydroxide Production

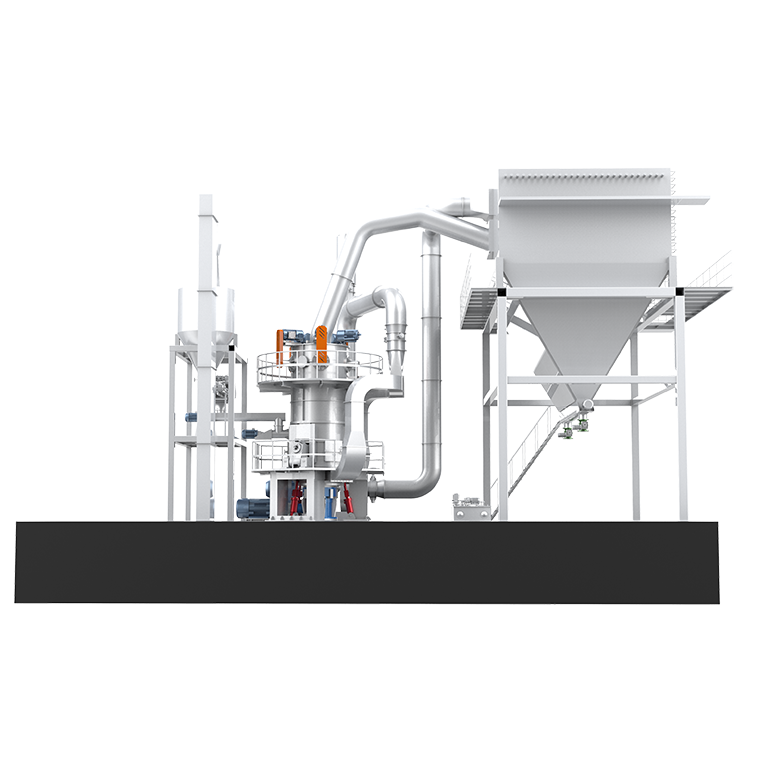

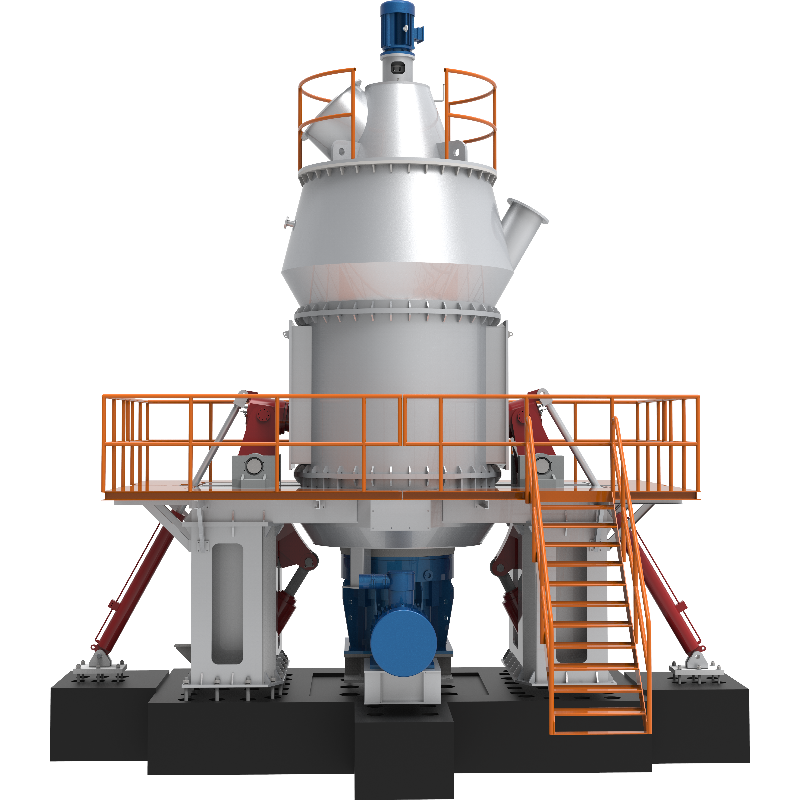

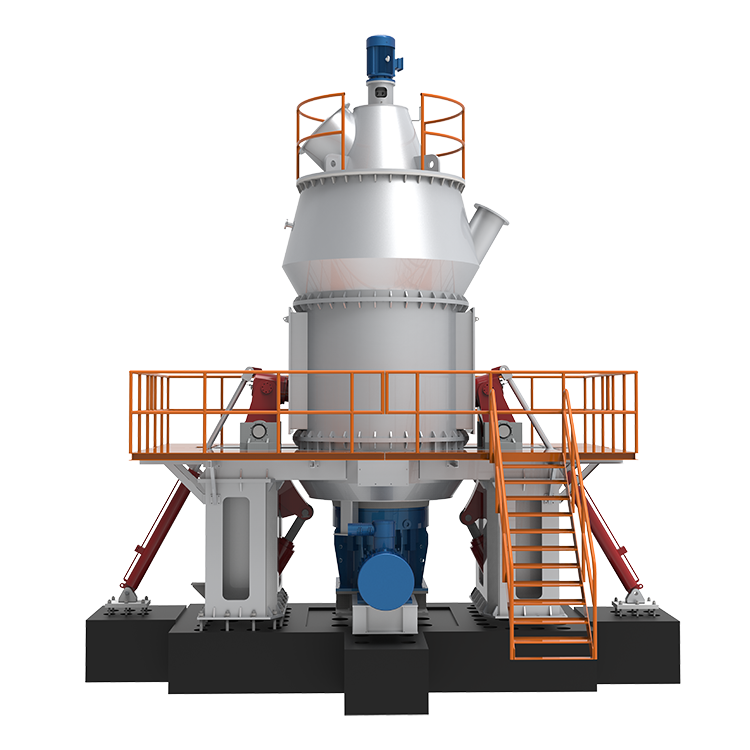

The core equipment of the calcium hydroxide powder selection system includes mills, classifiers, and dust collectors, with process configurations and parameters directly affecting product particle size. Taking Cronus’s CRW-S series precision classifier as an example, this equipment integrates advanced international technologies and employs aeronautical aerodynamics principles, combining suspension dispersion separation, horizontal vortex classification, cyclone collection, secondary separation of coarse powder, and bypass dust removal. Its innovative design features include:

- Multi-channel, high-efficiency, low-resistance separators arranged around the main body, simplifying the process flow, reducing dust collection load, and lowering investment costs.

- A secondary air classification device installed at the bottom of the coarse powder hopper, effectively separating fine particles adhering to coarse powder, improving classification efficiency.

- A unique dispersion structure in the separation chamber ensures uniform material distribution, creating optimal conditions for precise classification.

Impact of Particle Size on Calcium Hydroxide Performance

Specific Surface Area

Smaller particle sizes result in a larger specific surface area, enhancing reactivity. This is particularly advantageous in applications requiring high activity, such as catalysts and adsorbents. For example, in wastewater treatment, finer calcium hydroxide reacts more rapidly with pollutants, accelerating purification.

Solubility

Finer particles dissolve faster, which is beneficial in applications requiring quick hydroxide ion release, such as wastewater treatment and soil remediation. In acidic soil neutralization, finely ground calcium hydroxide dissolves rapidly, improving soil pH balance and promoting plant growth.

Flowability and Dispersion

Fine calcium hydroxide powder exhibits excellent flowability and dispersion, reducing agglomeration during transport, storage, and application. In construction materials, uniform dispersion ensures better mixing with other raw materials, enhancing product stability.

The Misconception: "Finer is Always Better"

While fine particle size offers advantages in certain applications, it does not mean that ultra-fine classification is universally optimal. Several factors must be considered in production.

Energy Consumption & Cost

As particle size decreases, energy consumption of mills and classifiers increases significantly. For instance, Cronus’s CRW-S classifier requires substantially more power when targeting 1000 mesh vs. 200 mesh. Additionally, finer particles generate more dust, increasing pollution control costs. Thus, balancing energy efficiency, cost, and environmental compliance is essential.

Market Demand

Different industries have varying particle size requirements:

- Construction: Coarser particles are preferred for fillers and structural strength.

- Agriculture: Finer particles are needed for soil conditioning and pest control due to higher solubility and reactivity.

Production must align with market-specific demands to meet customer needs effectively.

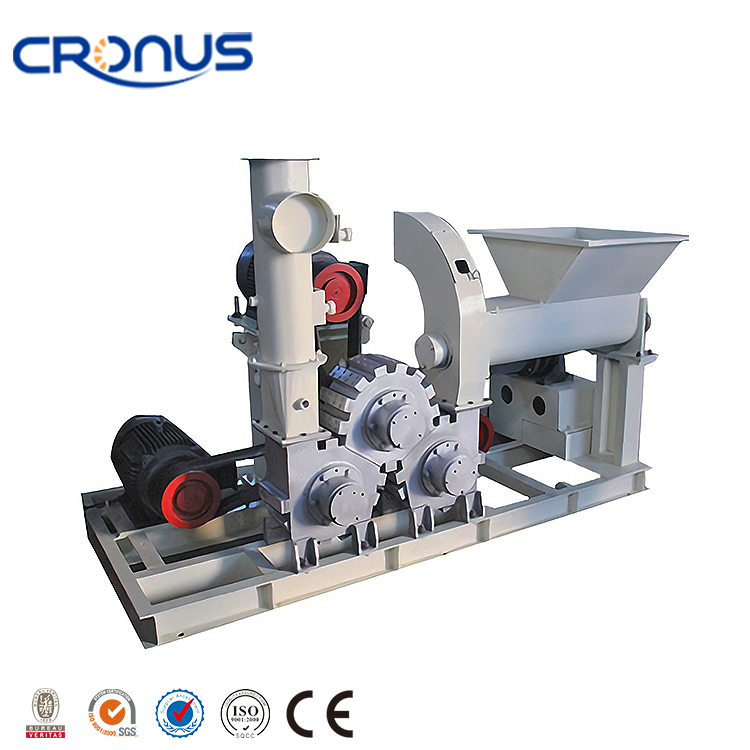

Equipment Capability

Not all classifiers are optimized for ultra-fine separation. Cronus offers multiple models, some excelling in fine powder production, while others are better suited for coarser classifications. Selecting the right system based on production goals and equipment performance ensures optimal results.

Optimization Strategies for Calcium Hydroxide Powder Selection

Selecting the Right Mill & Classifier

Choose equipment based on target particle size and market needs. Cronus’s CRW-S series is ideal for fine powder, while other models cater to different ranges. Regular maintenance and calibration ensure consistent performance.

Process Parameter Optimization

Adjust mill speed, feed rate, and classifier settings to refine particle distribution. Additionally, strict raw material quality control ensures stable production and product consistency.

Enhancing Environmental Management

Advanced dust collection and emission control technologies, such as those in Cronus classifiers, minimize pollution. Proper wastewater and exhaust treatment ensures compliance with environmental regulations, supporting sustainable production.

In calcium hydroxide production, powder selection systems should not blindly pursue ultra-fine particle sizes. Instead, manufacturers must balance performance requirements, market demand, equipment capabilities, and environmental factors. Cronus’s advanced classifier technology provides tailored solutions, helping businesses achieve optimal product quality, cost efficiency, and eco-friendly operations.