Calcite: Properties, Processing, and Applications

Calcite, a common carbonate mineral with the chemical formula CaCO₃, is widely distributed around the world. Its diverse properties and abundance make it a crucial material in numerous industries. Understanding its origin, processing methods, applications, and the equipment involved in its transformation is key to appreciating its significance.

Geographical Distribution of Calcite

- China

Calcite deposits can be found in almost every country. In the United States, notable sources include Indiana, Michigan, and Ohio, where large-scale mining operations extract high-quality calcite. China is also a major producer, with significant deposits in provinces like Guangxi, Hunan, and Inner Mongolia. In Europe, countries such as the United Kingdom, France, and Germany have their own calcite reserves. Additionally, calcite is mined in South America, particularly in Brazil, and in Africa, where countries like South Africa and Morocco contribute to the global supply. These deposits vary in quality and purity, which influences their suitability for different applications.

Guangxi: In this region, most of the calcite mines are exposed along the fault fracture zones, occurring in a vein-like form and stored underground. They are small in scale, and there are significant variations in quality and whiteness.

Nanzhao County, Henan Province: The total reserve of calcite resources is approximately 1 billion tons, and the total amount of identified resources is 200 million tons. Among them, the reserve of calcite that can be used for the production of food-grade calcium carbonate is about 50 million tons.

Chizhou and Xuancheng, Anhui Province: The reserve of the calcite mining area in the southern section of Lailongshan Mining Area in Qingyang County, Chizhou City, Anhui Province is about 140 million tons, accounting for 40% of the proven calcite reserves in Anhui Province.

Liangdang County, Gansu Province: The total resource reserve of calcite in the Huoqigou-Erlangba Mining Area exceeds 2.2 billion tons. The identified resource reserve of calcite is 2.26 billion tons, among which the first-grade ore is 610 million tons.

Linwu County, Hunan Province: The reserve of coarse-grained calcite marble ore resources (332+333) in Linwu is 12.727 million tons, and there is another resource amount of 1.524 million tons for the 334 category. The reserve of calcite minerals in Taoyuan County is about 80 million tons.

- The United States

Kentucky: There are abundant calcite deposits, mainly used for cement production and building materials. There is currently no exact public data on the specific reserves.

Tennessee: It has a large amount of high-quality calcite mines, which are widely used in industrial purposes. The reserve data is unclear.

- India

Rajasthan: The calcite deposits in this region are of relatively high quality and it is one of the globally renowned calcite production areas. There is a lack of accurate public data on the specific reserves. Wolkem, India's largest wollastonite producer, has a calcite mining lease in Rajasthan. It owns various minerals in multiple states of India, and it is expected that the reserves of these minerals will maintain its production for a long time in the future.

- Italy

Tuscany: It is rich in calcite resources and is a key production area for marble and decorative building materials. The reserve situation has not been clearly announced.

Sardinia: It is famous for its high-quality marble, and calcite deposits are widely distributed. There is currently no specific reserve data.

- Brazil

Santa Catarina: Calcite mines are used for the production of cement and other building materials, and there is a lack of reserve information.

Minas Gerais: The calcite deposits are of excellent quality, mainly used for agricultural and chemical products, and there is no exact reserve data.

- Mexico

Jalisco: Calcite deposits are mainly used in the cement, plastic, and paper industries, and there is no clear data on the reserves.

Texas (the part bordering the United States): The application of calcite mines is concentrated in the construction and environmental protection industries, and the reserves are unknown.

Processing of Calcite

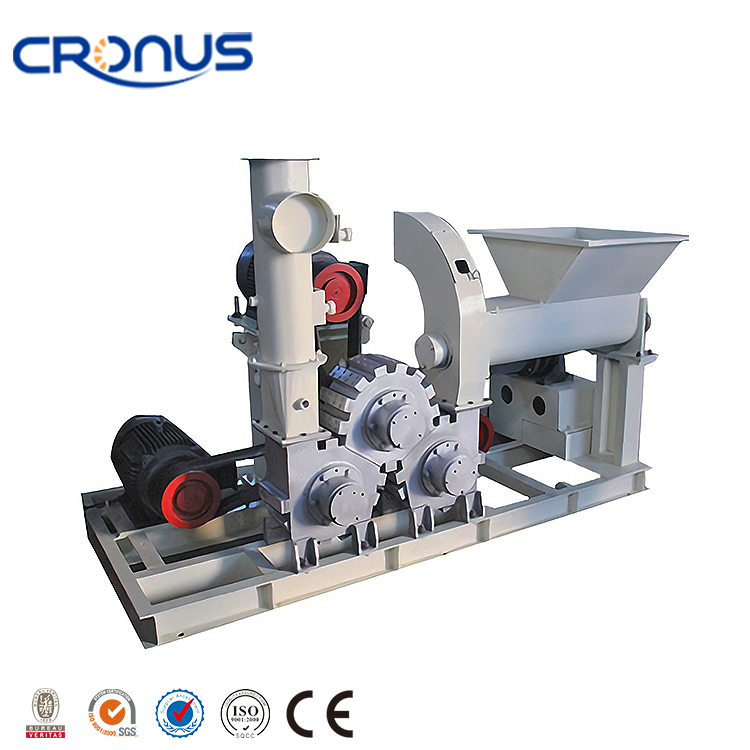

The processing of calcite begins with mining. Once extracted from the ground, the raw calcite ore needs to be processed to remove impurities and transform it into usable forms. The first step often involves crushing the large - sized ore into smaller pieces. Crushers, such as jaw crushers and impact crushers, are commonly used for this initial stage. Jaw crushers use a compressive force to break the ore, while impact crushers rely on impact forces to shatter the material, reducing it to a more manageable size for further processing.

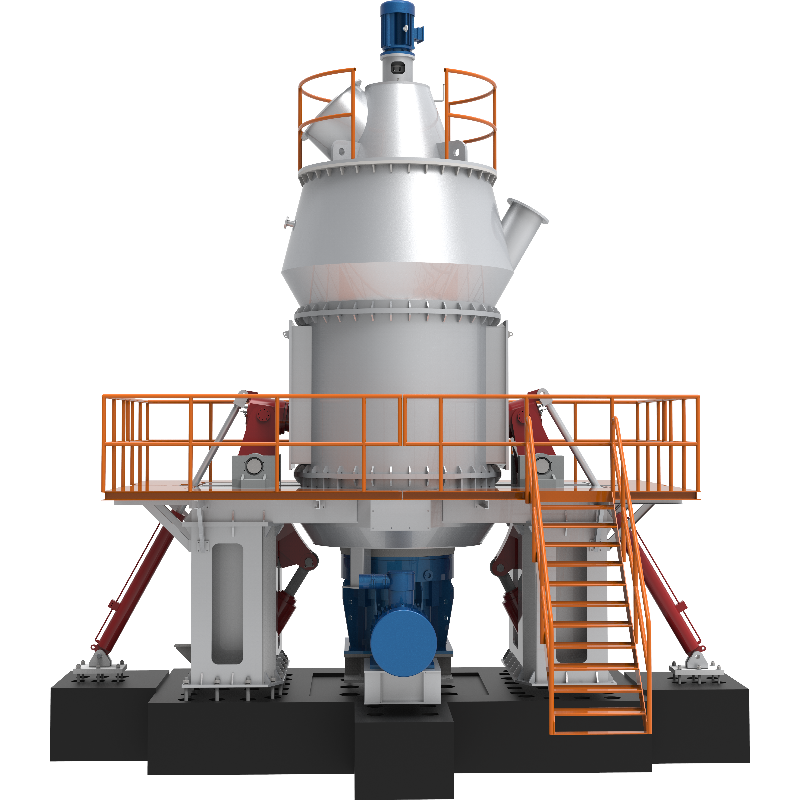

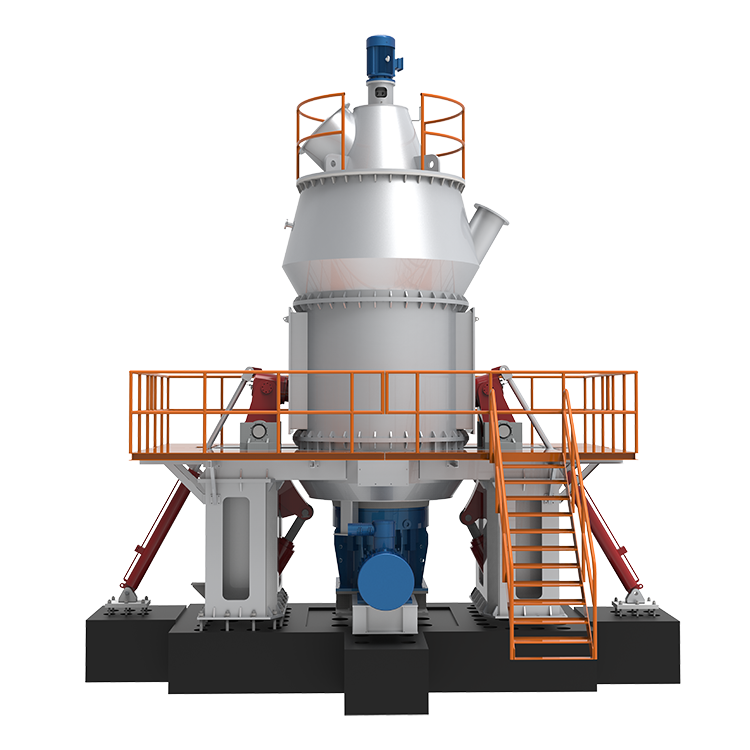

After crushing, the next stage may involve grinding the calcite into powder. Different types of grinding equipment are used depending on the desired fineness of the powder.

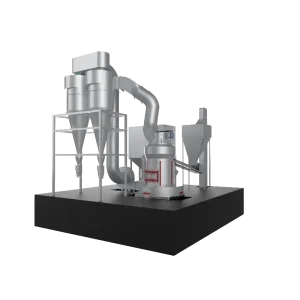

Raymond Mill for Calcite Powder

The Raymond mill is a popular choice for producing calcite powder. It consists of a main frame, a grinding roller, a grinding ring, and a classifier. As the grinding roller rotates around a vertical axis, it presses against the grinding ring, crushing and grinding the calcite particles. The classifier separates the ground powder based on particle size, allowing only the desired-sized particles to be collected. Raymond mills are efficient for producing medium - to fine-sized calcite powder, typically in the range of 80 - 325 mesh, which is suitable for applications such as paint, plastics, and rubber.

Ball Mill for Calcite Powder

Ball mills are another type of equipment used in calcite powder production. They are cylindrical containers filled with grinding media, usually steel balls. The container rotates, causing the balls to cascade and crush the calcite material. Ball mills can achieve a higher degree of fineness compared to Raymond mills and are often used for producing coarser to medium-fine powders. They are also suitable for continuous production and can handle large quantities of calcite ore.

Ultrafine Grinding Mill for Calcite Powder

For applications that require extremely fine calcite powder, such as in the pharmaceutical, cosmetics, and high-end coatings industries, ultrafine grinding mills are employed. These mills use advanced grinding technologies, such as jet milling or stirred-media milling. Jet mills use high-velocity air or gas streams to accelerate the calcite particles, which then collide with each other or against impact plates, achieving a very fine particle size, often less than 10 microns. Stirred - media mills, on the other hand, use a rotating agitator to stir the grinding media and the calcite material, providing a more intensive grinding action for ultrafine powder production.

Applications of Calcite

Calcite has a wide range of applications due to its unique physical and chemical properties. In the construction industry, it is used as a building material in the form of limestone, which is a sedimentary rock composed mainly of calcite. Limestone is used for making cement, a crucial component in concrete, bricks, and mortar. It provides strength and durability to these construction materials.

In the paper industry, calcite is used as a filler. It improves the brightness, opacity, and printability of paper. By adding calcite powder to the paper pulp, manufacturers can produce high-quality paper products suitable for various applications, from newsprint to high-end glossy magazines.

Calcite also plays an important role in the chemical industry. It is a key raw material for the production of lime (CaO) through a process called calcination, where calcite is heated to high temperatures. Lime is used in many chemical processes, such as water treatment, where it helps to adjust the pH of water and remove impurities, and in the steel industry, where it is used as a flux to remove unwanted substances during steelmaking.

Applications of Calcite Powder

Calcite powder, due to its fine particle size and high purity, has additional specialized applications. In the plastic industry, it is used as a filler and reinforcing agent. Adding calcite powder to plastics can improve their mechanical properties, such as strength, stiffness, and impact resistance, while also reducing production costs.

In the paint industry, calcite powder serves as a pigment extender. It helps to reduce the cost of paint formulations by replacing more expensive pigments, while also enhancing the paint's hiding power, durability, and gloss.

In the food and pharmaceutical industries, high-purity calcite powder is used. In the food industry, it is used as a calcium supplement in food products. In the pharmaceutical industry, it is used as an excipient in tablets and capsules, providing bulk and stability to the drug formulations.

Additional Knowledge about Calcite

Calcite has interesting optical properties. It exhibits birefringence, which means that light passing through a calcite crystal is split into two rays traveling at different speeds and in different directions. This property makes it useful in optical instruments, such as polarizing microscopes.

Calcite also has cultural and historical significance. It has been used in the production of decorative items and sculptures throughout history. In addition, calcite formations, such as stalactites and stalagmites in caves, are not only beautiful natural wonders but also provide valuable information for geologists studying the history of the Earth's crust and climate change.

In conclusion, calcite is a versatile mineral with a wide range of applications. Its availability in various parts of the world, combined with the diverse processing methods and equipment, allows it to meet the needs of multiple industries. As technology continues to advance, new applications for calcite and its processed forms are likely to be discovered, further enhancing its importance in our modern world.