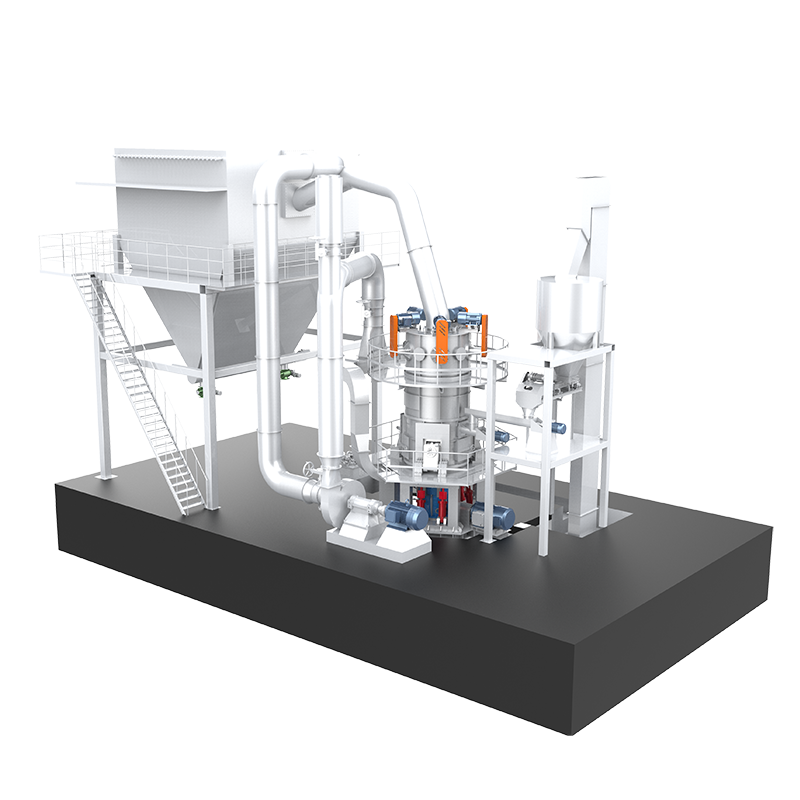

Cement grinding is mainly used in the production of cement silicate products. The Cement Mill is the key equipment for second grinding after the system pre-crushes the cement clinker. Our company continues to explore and summarize the long-term design, and production process. We have developed and produced many products with different specifications to meet different fineness requirements. And it is more prominent in cement grinding. HXJQ technical staff use appropriate transmission modes for different cement mill specifications and models. There are two methods, the edge drive method and the center drive method.

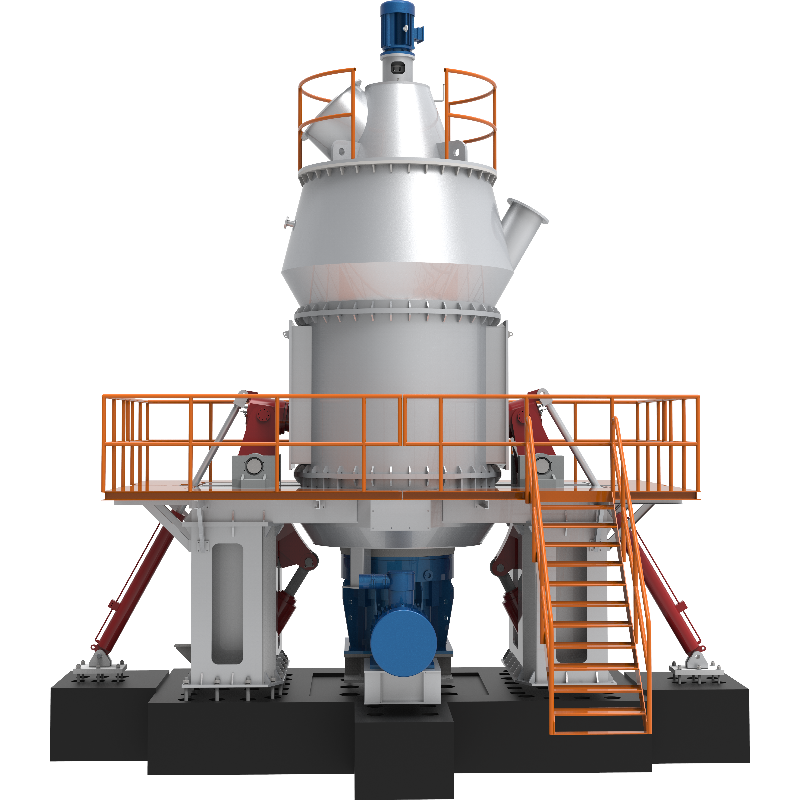

Simple structure, reliable operation

There are liner and plate liner in mill, structure is simple, operation is reliable.

Energy saving, durable

The bearing is improved and power consumption is reduced by about 10%, which has good energy-saving effect and strong durability.

Large production capacity

The mill output improves 15–20% than general mill. In addition, the finished product temperature can be reduced by 20-40°c.

Good grading effect

New grading liner and standard step liner are adopted in inner cylinder, which increases materials grinding surface area and has better grading effect.

- 5. Easy to install and maintain

- Adjustable lifting plates and fixed lifting plates are adopted in the new compartment structure, which is easy to install and maintain.

- 6. Good dust removal system

- Mill dust removal performance is very good. Less pollution and makes production reach the environmental standard.

- 7. Long service life of wearing parts

- With the technology updates, the wear parts of Cronus cement mill has longer service life and is easy to maintain and repair.