Development History

In December 2021

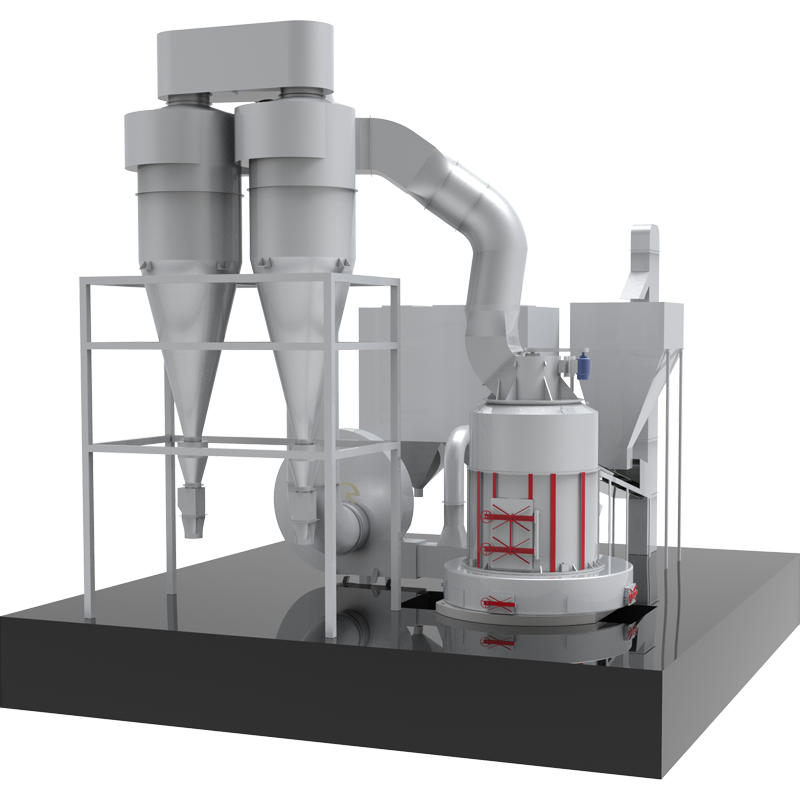

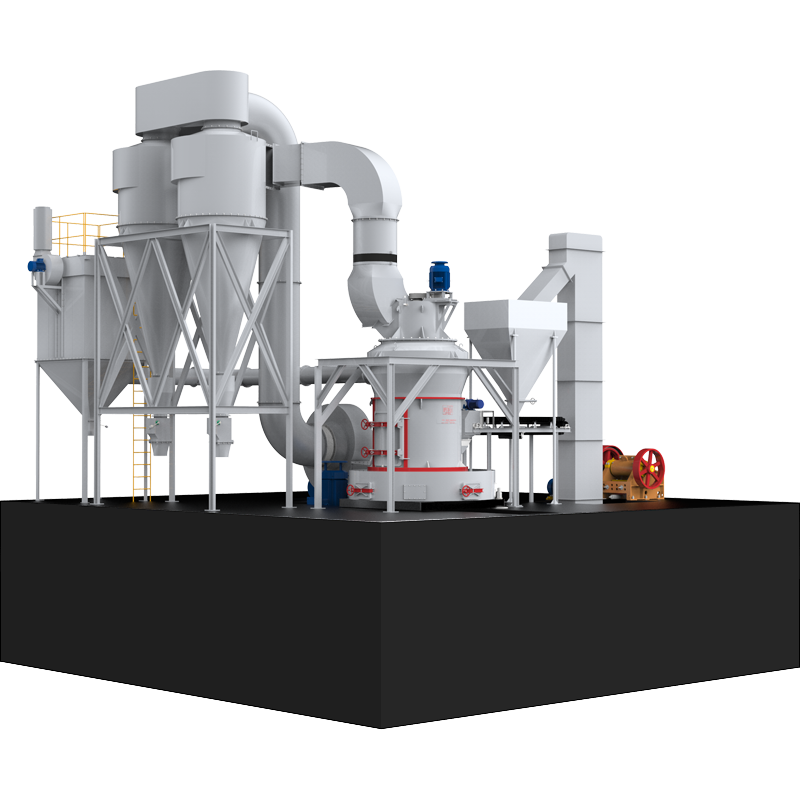

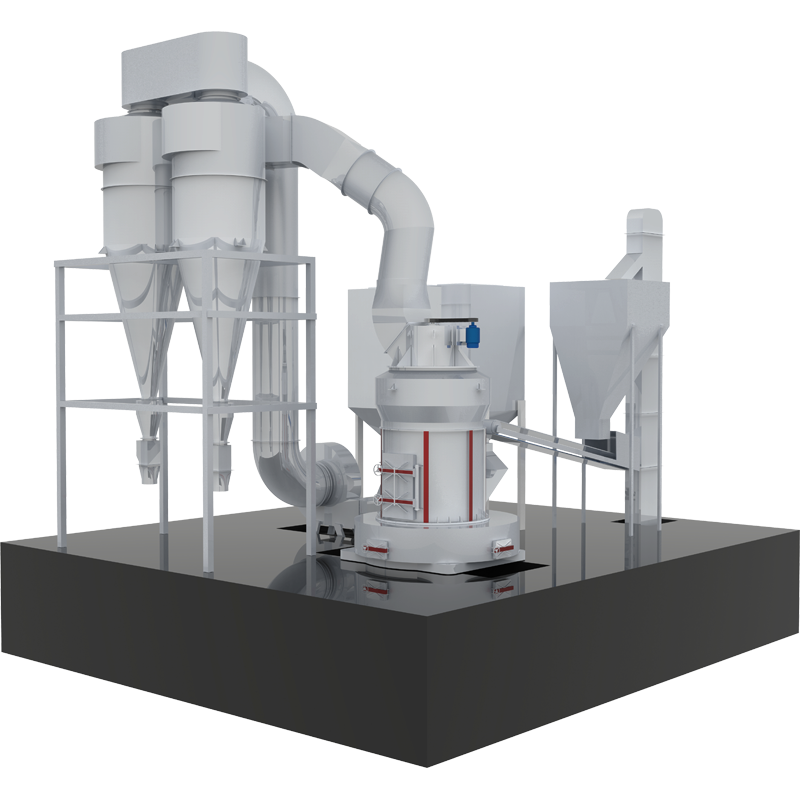

Developed GK1920 Pendulum Grinding Mill

In November 202

GK2500 new Pendulum Grinding Mill Passed Appraisal and Acceptance of New Products at the Autonomous Region Level

In November 202

GK2150 new Pendulum Grinding Mill Passed Appraisal and Acceptance of New Products at the Autonomous Region Level

In October 2021

eveloped GK2000 Pendulum Grinding Mill

In August 2021

Developed GK2150 Sand and Powder Integrated Grinding Machine

In June 2021

Developed GK1700 Pendulum Grinding Mill

In March 2021

GKLMX1200 Superfine Vertical Roller Mill Successfully Tested

In December 2020

Developed GK1850 Pendulum Grinding Mill

In July 2020

GK1720A new Pendulum Grinding Mill Passed Appraisal and Acceptance of New Products at the Autonomous Region Level

In July 2020

GK1620A new Pendulum Grinding Mill Passed Appraisal and Acceptance of New Products at the Autonomous Region Level

In June 2020

Developed GK1620 Sand and Powder Integrated Grinding Machine

In September 2019

Developed Reducer for Large-scale Grinding Mill

In July 2019

the First Intelligent Production Line of Slaked Lime Powder Successfully Tested

In April 2019

Launched Energy-saving, Environmentally friendly and High Efficient GKXF5R Powder Separator with Independent Intellectual Property Rights

In January 2019

Developed GK1620A Pendulum Grinding Mill

In July 2018

Developed GK1720A Pendulum Grinding Mill

In March 2018

Launched GKW1270 Micro Powder Mill

In June 2018

Developed GK2500 Pendulum Grinding Mill